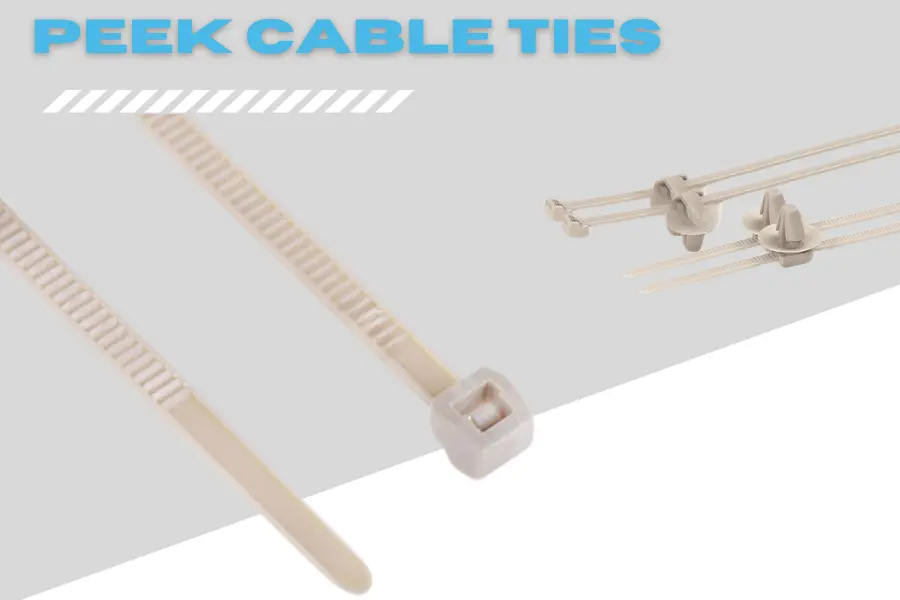

| PEEK CABLE TIES | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item no | Length | width | maximum bundle diameter | load-bearing capacity | ||||

| IN | MM | IN | MM | IN | MM | Lbs | N | |

| 1M-C71 | 3.9 | 99 | 0.098 | 0.87 | 0.87 | 22 | 3.9 | 99 |

| 1.5M-C71 | 5.6 | 142 | 0.098 | 1.25 | 1.25 | 32 | 5.6 | 142 |

| 2S-C71 | 7.4 | 188 | 7.4 | 188 | 188 | 48 | 7.4 | 188 |

| 2S-M71 | 7.4 | 188 | 0.19 | 1.88 | 1.88 | 48 | 7.4 | 188 |

A typical example is the application of downhole drilling electronics at elevated temperatures and in hostile chemical environments for the oil and gas industry. Here, we will find cables and components joined together with high temp zip tie with unusually high thermal stability and chemical corrosion resistance.

PEEK cable ties find application even in nuclear power plants, which must withstand radiation and elevated temperatures. Their non-conductive nature and low flammability allow for the applications of their use in holding other cables.

Manufacturing an optical component using a vacuum oven requires a stable material in both high vacuum conditions and at increased temperatures. Therefore, PEEK high temp zip ties remain the ideal candidate for this job due to their low outgassing properties, enabling them to stay stable at high temperatures.

Wiring in commercial ovens, grills, and other cooking equipment has to run at high temperatures. For securing this wiring, there can be various equipment, such as PEEK high temperature cable ties, which are quality-dependent in their functioning while being continuously exposed to heat, according to food safety standards.

High temperature lighting The use of high-intensity lighting fixtures in, for example, an industrial or stage situation results in generating a substantial amount of heat. Such fixtures have PEEK high temperature cable ties within them to keep everything organized and to fix everything properly to allow it to stay arranged in a high-temperature setting while managing the cabling safely.

This is mainly due to the good thermal and mechanical features of the material, which means there are varied applications of high temperature cable ties in ovens operating in a high temperature wire ties mode.

This is because of the high temperature and electric stress that the transformers and transducers frequently have to work in. The high temperature cable ties offer excellent high dielectric strength and thermal stability, which can secure windings and other components.

In this case, wire harnesses will have to withstand harsh environmental conditions, such as extremely high temperatures, chemicals, and physical stress, which could occur in the industries of aerospace, automotive, and defense. High temperature cable ties are chosen for their robustness and reliability in such applications. Manufacturing of Chemicals Because most chemical manufacturing processes contain a highly corrosive substance and high temperature, high temperature cable ties with eyeletsoptimally offer exceptional chemical resistance and thermal stability, ideal for safely securing both cables and components.