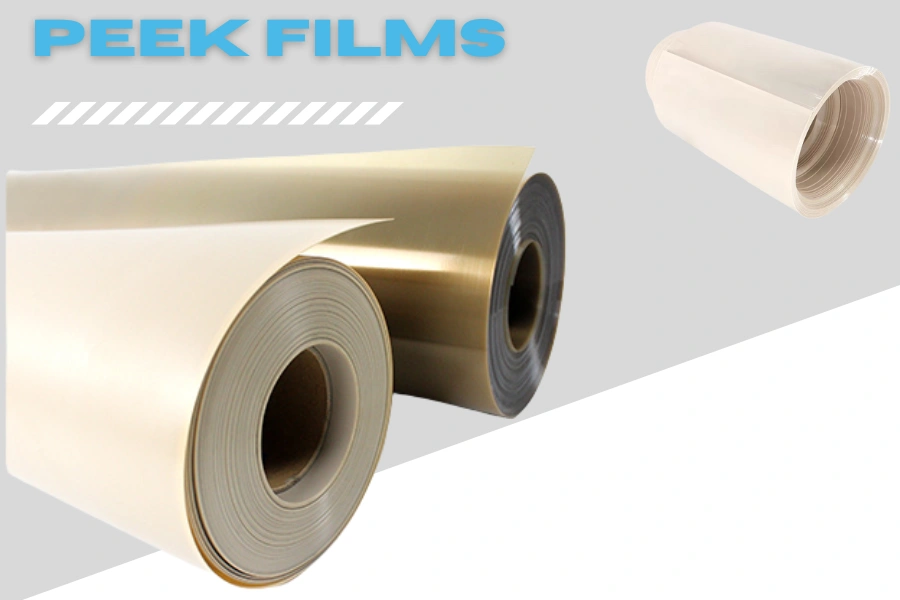

The molecular arrangement of amorphous PEEK film is more chaotic, there is no obvious crystallization area.

Semi-crystalline PEEK film in the molecular arrangement of the more orderly, some of which formed a crystalline structure, there are also amorphous regions.

Performance characteristics: semi-crystalline PEEK film has high strength and rigidity, while retaining a certain degree of flexibility, its density is relatively high, good mechanical properties.

Applications: Due to its good mechanical properties and chemical stability, semi-crystalline PEEK films are commonly used in applications requiring high strength and rigidity, such as aerospace, automotive industry, electronic devices, etc.

A mineral filled polyether ether ketone (PEEK) film is a film material made by adding mineral fillers (glass fibers, carbon fibers, carbon black, calcium and magnesium silicates) to a polyether ether ketone matrix.

Mineral-filled PEEK increases strength and stiffness.

The addition of filler minerals such as carbon black or glass fibers can significantly improve the wear resistance of PEEK.

Increased electrical conductivity.

The addition of calcium and magnesium silicates improves the thermal stability and heat resistance of PEEK, especially in high temperature environments.

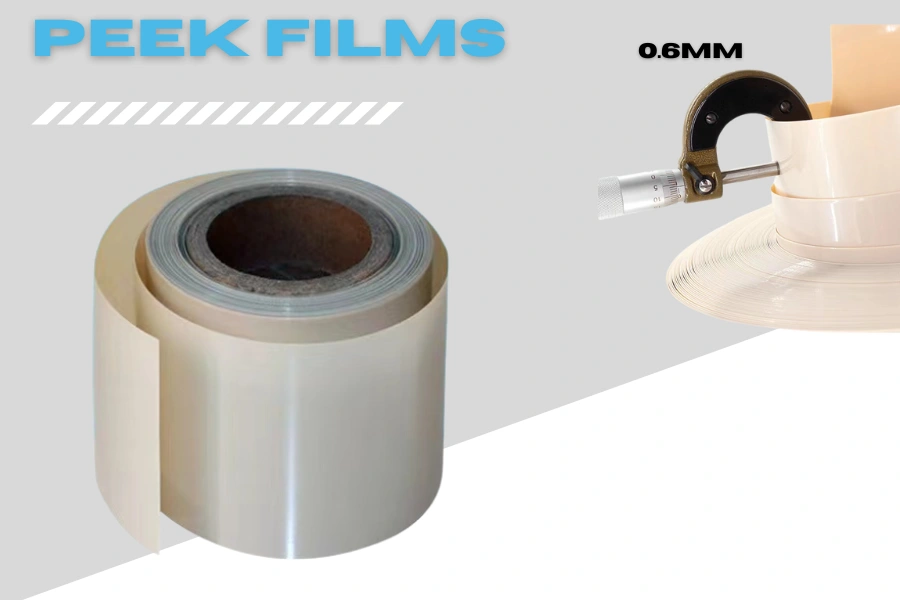

| PEEK film size table | ||||

|---|---|---|---|---|

| Products name | Color | Texture | Thickness(µm) | width(mm) |

| peek films | nature or black | polished/polished | 100-250 | 1360 |

| polished/Matte | 250-400 | 1360 | ||

| Matte/Matte | 500-800 | 680 | ||

CD and DVD motor gaskets, speaker film, circuit board substrates, 5G antenna substrates and other related components, supercapacitors

Sealing gaskets, thrust washers, motor insulation, high temperature circuit boards

Oil and gas cable wrappers, RFID tags, solenoid wire insulation, pressure sensors, flexible film heaters, conveyor belt devices, high performance labels

Insulating films, thermoformed parts, carbon fiber composites, multifunctional adhesive tapes

Liquid crystal glass polishing frames, silicon wafer carriers, wafer and glass conveyor belts

Process tape devices, pharmaceutical labels, membrane switches, specialty packaging

| PEEK film Properties table | |||

|---|---|---|---|

| Property | Test Method | Units | Value |

| Density | ASTM D792 | g/cm³ | 1.26~1.29 |

| Average Water Absorption Equilibrium,24h | ASTM D570 | % | 0.04 |

| Heat Shrinkage | ISO 11501 (200℃) | % | 0.8~4.7 |

| Tensile Strength at Yield (MD) | ASTM D882 | MPa | 70~90 |

| Tensile Strength at Yield (TD) | ASTM D882 | MPa | 68~86 |

| Tensile Strength at Break (MD) | ASTM D882 | MPa | 120~186 |

| Tensile Strength at Break (TD) | ASTM D882 | MPa | 112~115 |

| Elongation Ultimate (MD) | ASTM D882 | % | 186~225 |

| Elongation Ultimate (TD) | ASTM D882 | % | 145~180 |

| Tensile Modulus (MD) | ASTM D882 | MPa | 1993~2755 |

| Tensile Modulus (TD) | ASTM D882 | MPa | 1964~2568 |

| Melting Point | ISO11357 | ℃ | 343 |

| Coefficient of Thermal Expansion (< Tg) | ISO11359 | ppm/K | 55~60 |

| Glass Transition Temperature | ISO11357 | ℃ | 153 |

| Dielectric Strength (25 μm) | ASTM D149 | KV/mm | 150 |

| Volume Resistivity @25°C,50%RH | ASTM D257 | Ω·m | 10^16 |

| Dielectric Constant (50MHz) | ASTM D150 (50MHz) | 3.12~3.3 | |

| Loss Tangent (50MHz) | ASTM D150 (50MHz) | 0.004~0.005 | |

More PEEK raw material properties

Thermoplastic resin, melting point 343℃, UL recognized long-term use temperature of 260℃. It maintains high strength at -198℃.

self-lubricating, minimal weight loss by abrasion, with outstanding self-lubricating properties.

In the high temperature, high pressure, high frequency and high speed, high humidity and other environments still have excellent insulation and stability.

In the usual chemicals that can dissolve or destroy it is only concentrated sulfuric acid, its corrosion resistance is similar to nickel steel.Good radiation resistance

Excellent resistance to all kinds of radiation.

A certain thickness of PEEK film has a self-flame retardant, combustion products of low smoke and non-toxic.

Hydrolysis resistance, low water absorption (0.04%), can be used for a long time at 200 ℃ under water vapor.