PEEK Plastic Sheets Grade

peek 450g sheet Is extruded from PEEK pure resin, which has good toughness and strong impact resistance.

This is manufactured from pure polyether ether ketone resin, which is the toughest and most impact resistant of all PEEK grades. Pure PEEK can be sterilized using convenient sterilization methods (steam, dry heat, ethanol, and Y-rays), and the raw material components used in the manufacture of PEEK comply with European Union and U.S. FDA regulations on food safety.

PEEK 450Gl30 This material is filled with 30% glass fiber reinforced grade plastic, than PEEK has better rigidity and creep resistance, as well as better dimensional stability, the manufacture of structural parts is ideal. At high temperatures for a long time to withstand fixed loads.

CF30 PEEK Sheet - Black PEEK sheet

The material is filled with 30% carbon fiber reinforced, than PEEK-450CA30 has better mechanical properties (higher modulus of elasticity, mechanical strength and creep) and more wear-resistant, but also add carbon fiber reinforced plastic than unreinforced PEEK plastic has 3.5 times the thermal conductivity faster heat dissipation from the bearing surface.

ESD PEEK rod can a avoid the harm of voltage discharge to people or objects. Based on static electricity control and permanent dissipation of static charge, this kind of plastic can provide high-level safety for application fields.

AST PEEK rod is based on PEEK raw material which is mixed with carbon fiber. carbon black, metal fber, metal powder, permanent antistatic masterbatch etc. , so as to achieve the functions of conductivity and electromagnetic interference shielding.

Main application areas of PEEK sheets

- Fuel filters: used as filter components in aircraft fuel systems for maintaining fuel cleanliness.

- In-cabin seat and dining table: PEEK plates can manufacture lightweight cabin seat frames and dining tables due to its lightweight and high-temperature resistance.

- Radar cover: excellent electrical insulation and excellent heat resistance make PEEK plates suitable for radar cover.

- Landing gear components: manufacturing lightweight components of landing gear for reducing the overall weight.

- Specific models include TECAPEEK, which Ensinger provides for such uses, these come in thicknesses ranging from 5mm to 150mm.

- ABS anti-lock braking system: PEEK plates can replace metal materials to make the ABS components of an automobile.

- Seals and gaskets: used for seals within engines and gearboxes to ensure sealing performance.

- Bearings and sliders: PEEK sheets is often used to make the bearings and sliders in automobiles due to its wear resistance.

- For instance, the KetaSpire® PEEK sheet products have superior wear resistance and structural strength and thus are ready for application in automotive components.

- Insulation materials: These are used to fabricate electrical insulation parts such as connectors and switches under high-temperature conditions.

- Wafer carriers: It finds its application in semiconductor manufacturing in preparing wafer carriers with excellent thermal properties and electrical insulation.

- PEEK grades like KetaSpire® PEEK sheet can work in electronic machinery under very high temperatures and pressures.

- Surgical tool: Surgical tools and implants are also made from PEEK sheet owing to its biocompatibility and corrosion-resistant nature

- Dental tool: Dental tools and equipment made from PEEK sheet exhibit strength and lightweight features.

- Product lines under the brand name PEEK-Optima™ are constructed for medical applications and well within the norm of biocompatibility.

- Static-sensitive environment: They are also in use in semiconductor and integrated circuit manufacturing to avoid static damage to electronic components.

- Clean room equipment: They can be used to create work surfaces and brackets within the clean rooms to reduce the prevalence of static interference.

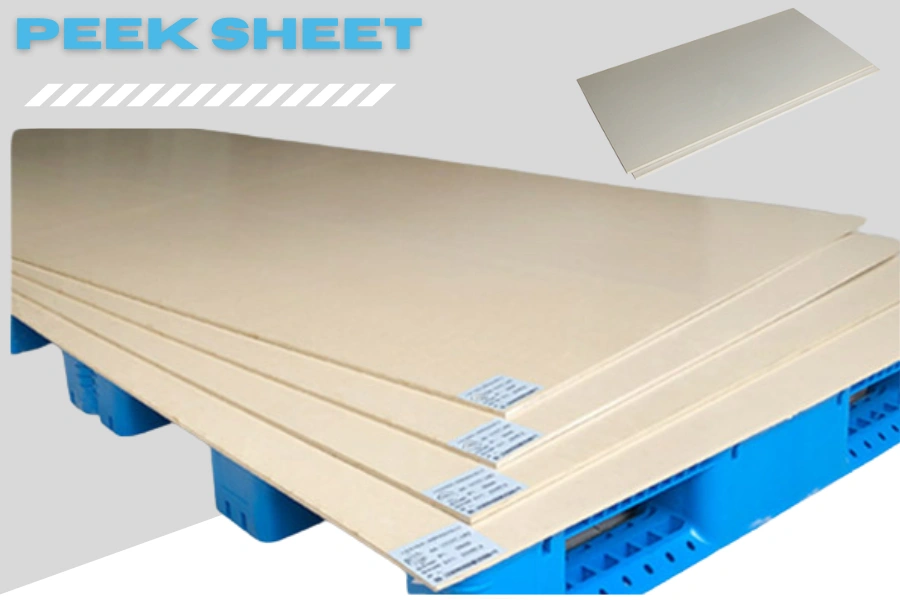

Polyetheretherketone sheet size

The thickness of peek plastic plate ranges from 0.1mm to 205mm, and the maximum width can be 1250mm, see the following parameter table.

| T*W*L(mm) | Weight(kg) | T*W*L(mm) | Weight(kg) |

| 1*610*1220 | 1.1 | 25*610*1220 | 26.33 |

| 2*610*1220 | 2.11 | 30*610*1220 | 31.9 |

| 3*610*1220 | 3.72 | 35*610*1220 | 38.48 |

| 4*610*1220 | 5.03 | 40*610*1220 | 41.5 |

| 5*610*1220 | 5.068 | 45*610*1220 | 46.23 |

| 6*610*1220 | 6.654 | 50*610*1220 | 53.35 |

| 8*610*1220 | 8.62 | 60*610*1220 | 62.3 |

| 10*610*1220 | 10.85 | 100*610*1220 | 102.5 |

| 12*610*1220 | 12.55 | 120*610*1220 | 122.6 |

| 15*610*1220 | 15.85 | 150*610*1220 | 152.71 |

| 20*610*1220 | 21.725 | | |

| T:Thicness | W:width | L:long | |

About our services

- The PEEK plastic sheets produced by BW are processed by continuous extrusion process, we have 3 advantages:

- Very high surface finish, flat and smooth.

- Good dimensional uniformity, no one side is thick and the other side is thin.

- Uniform color with no color difference

- Adequate stockpiles are available

PEEK Sheets sizes and specifications to meet regular daily needs, daily stock is sufficient, thickness from 0.1mm to 205mm, can be produced in bulk.

- Support BW PEEK Sheets Cutting & CNC machining

PEEK sheets made by a continuous extrusion method typically have lengths of 600 and 3000 mm, although they can also be trimmed to fit specific customer requirements.