High-performance thermoplastic resin PEEK (Polyether Ether Ketone) is prized for its outstanding chemical and thermal stability in demanding applications. When moulding PEEK, there are a handful of things to be considered, not the least of which involve the use of heated molds, material strength, and specific processing techniques required.

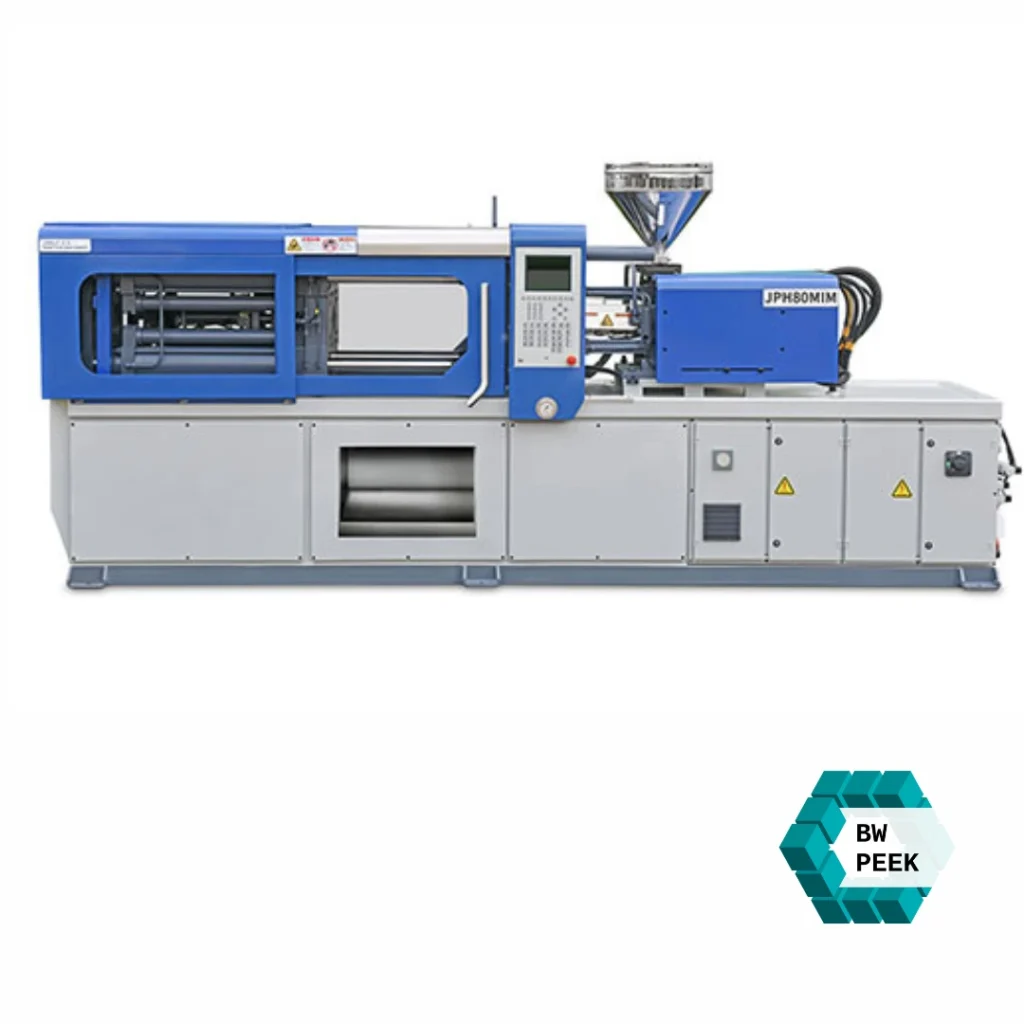

As PEEK needs to be heated during injection moulding, a reliable heating and temperature measuring system is required in the mold. They need to keep the mold strong enough under high temperatures and pressures.

The requirements for mold materials increase substantially when using fiber-reinforced PEEK polymer, as the mold’s cycle life can be shortened.

During PEEK injection moulding there are a few things to monitor, some of which are important.

PEEK injection moulding are similar in structure to standard molds but require special considerations:

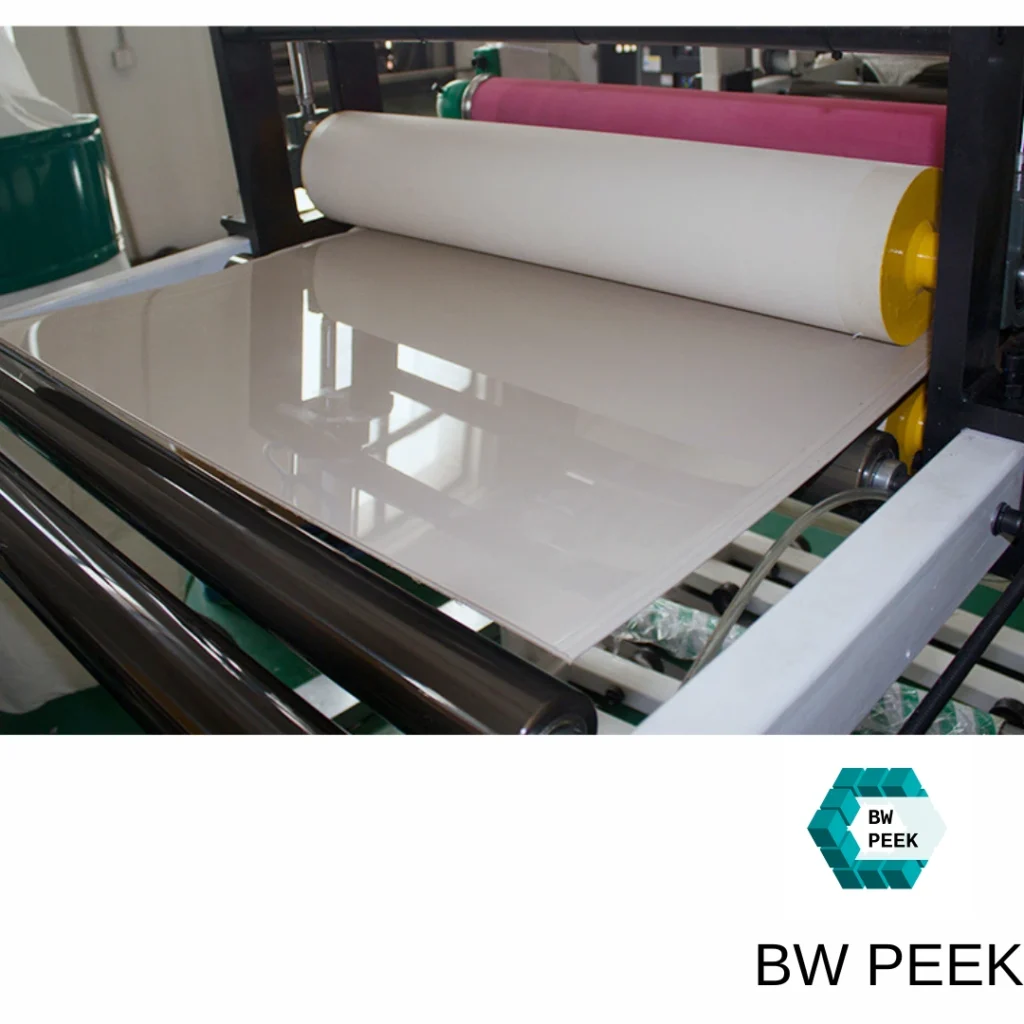

To have the best results, the PEEK resin should be less than 0.02% w/w of the granular polymers, and should therefore be dried until below atmospheric moisture absorption of 0.5% w/w. The dried PEEK resin can then be placed in an air circulation oven and dried at 150 ℃ for at least 3 hours for example, or 160 ℃ for 2 hours.

For drying in a drying oven, the thickness of the raw material in the tray should not be larger than 25 mm., and shading should be prevented.

The pure peek resin and residual peek resin can be recycled and injected into one another.

The use of recycled peek resin (without fillers) should not exceed 30 percent of the total weight and recycled peek resin with fillers should not exceed 10 percent of the total.

we examine if the peek polymer is degraded at 360°C if the machine is shut down during the melting process under the condition that the polymer residence time does not exceed 1 hour. Conversely, the material degrades rather insignificantly if the machine is disabled for more than 1 hour.

But if it exceeds an hour, the barrel temperature should be lowered to 340 ℃, at 340 ℃, the peek polymer can be kept for a few hours to maintain the stability of its continuation in processing must increase in barrel temperature such as more than 3 hours, the barrel should be cleaned.

The peek melting point at 343 °C so the conventional machines that can hold high melt temperatures in 360˚C to 400 °C range are capable of a molten state.

The short residence time of PEEK polymer is essential as the life of the component is limited while processing, considering the high temperatures involved. The ideal barrel capacity is 2 to 5 times the total weight of the shot.

The PEEK melting point is very high and if the temperature drops too low the melt quickly solidifies even below 343°C. Therefore, a large enough heater has to be installed at the nozzle to prevent ‘cold injection’ from occurring due to the temperature drop.

A minimum L/D ratio of 16:1 is recommended, however, it is felt that ratios between 18:1 and 24:1 would be preferred.

Unreinforced grade — 360-380℃; reinforced grade — 380-400℃.

The mold surface temperatures are 175-205℃.

General injection pressure of 70-140MPa.

Medium to high speed.

It is recommended to set the back pressure at 0~1.0 MPa (0~10 kgf / cm2).

The screw speed tends to be 50 to 100rpm, for high balance grades screw speed should be run lower for the reinforcing grades.

Unfilled grades shrink at rates of approximately 1.2–2.4%, and filled grades shrink at rates of 0.1–1.1%.

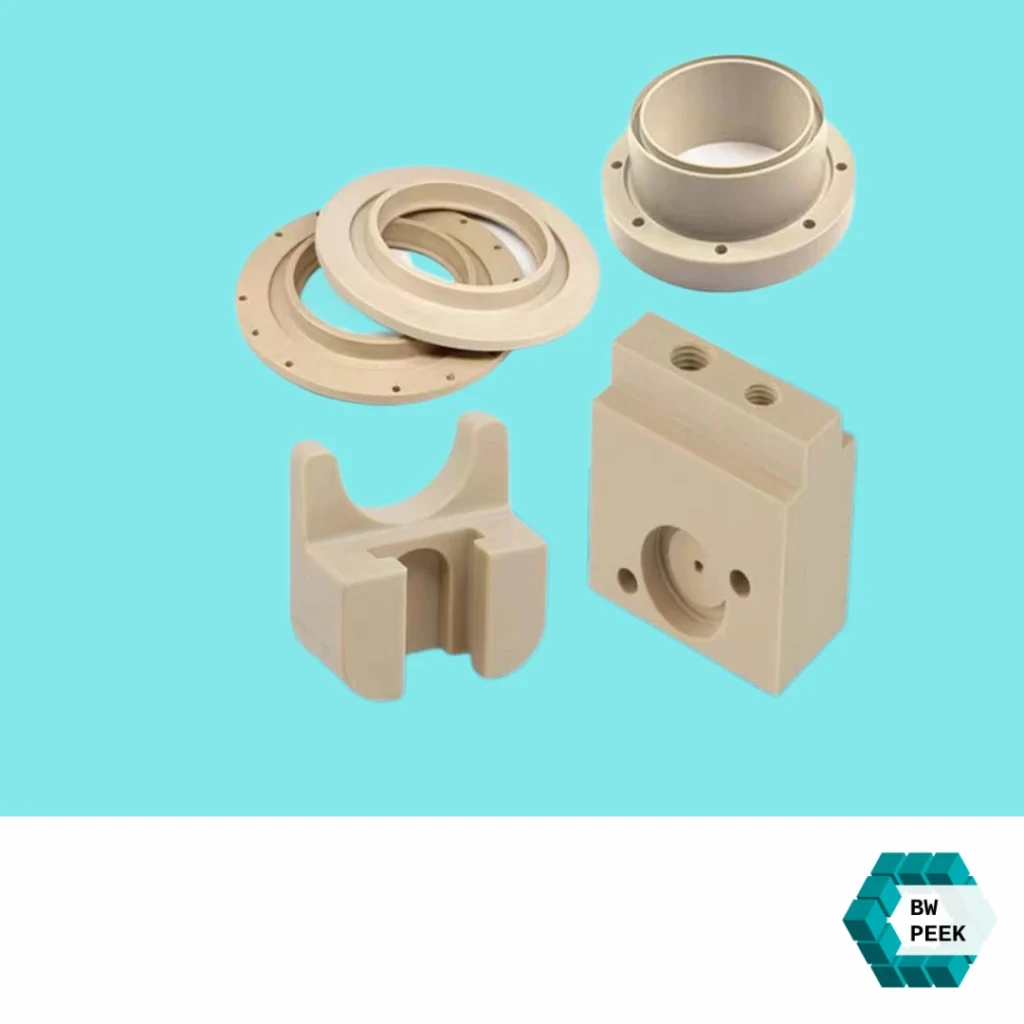

It can proceed for secondary processing like bonding, tapping, pressing, metal inserts, cutting, and surface metallization.

If internal stresses are not managed, deformation can occur. Key factors include:

These PEEK components are subjected to secondary processing, e.g. bonding, tapping, and machining. However, the deformation is not allowed to happen without managing the internal stresses.

Managing Internal Stresses

PEEK sheets

PEEK Parts

PEEK Tubing

PEEK Seals&Ring

PEEK Bearings

PEEK Valves

PEEK Medical implants

The ideal manufacturer for the PEEK injection moulding should be experienced when it comes to minimizing risk. The experience can be used to design the mold as well as set processing parameters to optimize performance and quality.

BW PEEK has advanced production capabilities such as continuous extruders, large horizontal and vertical injection moulding machines, precision peek injection moulding machines, and CNC machining centers. We are able to design and make extrusion, injection, or compression molds according to the customers’ specifications to which high-quality samples and mass production are guaranteed.