PEEK 650PF application

Seals and Gaskets:

Specific Applications: This was used in the automotive industry for seals of the engines.

Model: As for the 650PF material, it can be processed to become high-performance sealing gaskets that have a high tolerance to heat and chemical erosion.

Food Processing Equipment Parts:

Specific Applications: Ezio is utilized in components of valves and pumps for food processing equipment.

Model: Food industry applications for valves and pumps can discover 650PF to produce parts such as valve seals and pump cases as it has FDA food contact approval.

Chemical Processing Equipment:

Specific Applications: It is employed in pump housings and valves of chemical plants and is highly demanded in automotive industry.

Model: 650PF material is ideal for manufacturing pump housings and valves that shall offer the desired chemical endowments of high ACPI and high mechanical properties to guarantee use in corrosive service for several years.

Material Properties:

Mechanical Data:

Thermal Data:

Flow:

Miscellaneous:

Typical Processing Conditions:

Medical Devices:

Specific Applications: Surgical Stainless Steel is employed in the making of instruments to be utilized in surgeries or operations and also in the production of certain implants.

Model: The sterilization and FDA food contact of the PEEK 650G material can be used for the preparation of surgical clips, bone screws, and other medical parts that need high strength and chemical corrosion resistance.

Semiconductor manufacturing equipment:

Specific application: vacuum chucks, fixtures used during the semiconductor processing.

Model: A newly developed aluminum-magnesium alloy, PEEK 650G material, is ideal for high-performance AOI vacuum chucks and fixtures in semiconductor manufacturing equipment and has passed stability tests in high temperature and severity chemical environments.

Electronic insulation materials:

Specific application: previously employed for the production of electrical insulating materials, constantly delivering superior results.

Model: It also shows that PEEK 650G can be applied to produce the layers of cable insulation, the connectors' shells and other elements of electronics that should possess high levels of insulation and heat stability.

Aerospace components:

Specific application: used in the fabrication of interior surface components and structures of the aircraft.

Model: Due to its high strength, low density and ability to withstand high temperatures, PEEK 650G material can also be used to manufacture several components of aircrafts; seats, vehicle bodies, and fuse-lineers amongst others.

Material Properties:

Mechanical Data:

Thermal Data:

Flow:

Miscellaneous:

Electrical Properties:

Fire Smoke Toxicity:

Typical Processing Conditions:

Peek WG101 is a high-performance polyaryletherketone (PAEK) material with wear additives for thin-wall cross-section or long flow inherent strength, stiffness, and rigidity.

The notable characteristics of material very high resistance to wear, very low friction and low coefficient of thermal expansion.

Material Type: Hyper durable high performance thermoplastic (Polyaryletheretherketone, PAEK) with added abrasion resistant additive.

Application:

In Bushings WG101 performs well at high temperature high speed and is suitable for the bushings in different industrial machinery and equipment, ensuring stable running in long term and minimal maintenance necessity.

Sliding Bearing: Because of low friction coefficient and high abrasion resistance characteristic, WG101 is widely used in processing or reforming various sliding bearings and other friction parts that have extremely high requirements for abrasion resistance.

Pump and valve components: Under difficult and tough service conditions where chemical resistance and mechanical properties are primary requisites, these components are made of PVDF.

Tensile Strength

Rupture (23°C): 195 MPa

Rupture (125°C): 125 MPa

Rupture (175°C): 85 MPa

Rupture (225°C): 65 MPa

Rupture (275°C): 55 MPa

Tensile elongation (at break, 23°C): 1.8%

Tensile modulus (23°C): 19.5 GPa

Flexural Strength

23°C: 290 MPa

125°C: 220 MPa

175°C: 140 MPa

275°C: 70 MPa

Flexural modulus (23°C): 17 GPa

Compressive Strength

23°C: 230 MPa

120°C: 160 MPa

200°C: 65 MPa

250°C: 45 MPa

Charpy impact strength

Notched (23°C): 5.0 kJ/m²

Unnotched (23°C): 35 kJ/m²

Izod impact strength

Notched (23°C): 6.0 kJ/m²

Unnotched (23°C): 35 kJ/m²

Thermal properties (ISO 11357, ISO 11359, ISO 75-f, ISO 22007-4).

Melting point: 343 °C

Glass transition temperature

Start: 143 °C

Midpoint: 147 °C

Coefficient of linear thermal expansion

Below Tg in the flow direction: 9 ppm/K

Average below Tg: 35 ppm/K

Above Tg in flow direction: 10 ppm/K

Average above Tg: 85 ppm/K

Heat deflection temperature under load (1.8 MPa): 343 °C

Thermal conductivity

In flow direction (23°C): 2.2 W/m/K

Average (23°C): 1.3 W/m/K

Flow properties (ISO 11443).

Melt viscosity (400°C): 325 Pa.s

Miscellaneous (ISO 1183, ISO 868, ISO 62-1, IEC 60093).

Density (crystalline): 1.44 g/cm³

Shore D hardness (23°C): 85

Water Absorption

Saturated, 23°C: 0.3%

Saturated, 100°C: 0.6%

Volume resistivity (23°C, 1V): 1.0E+6 Ω-cm

Typical Processing Information:

Drying temperature / time: 150°C / 3h or 120°C / 5h (residual moisture <0.02%)

Temperature settings: 370 / 375 / 380 / 385 / 390°C (nozzle)

Hopper temperature: up to 100°C

Mold temperature: 180°C - 210°C

Mold shrinkage and spiral flow:

Spiral flow: 390°C nozzle, 200°C mold, 1 mm thick section: 135 mm

Mold shrinkage (ISO 294-4)

Along the flow direction: 0.0%

Vertical flow direction: 0.5%

PEEK ESD101 is high performance thermoplastic material as it has low electrostatic discharge control of 10nA and low outgassing emissions. It must be noted that molding conditions do not have an impact on its ESD performance provided processing conditions as recommended by the company are adhered to in the process.

Material type: A high-performance thermoplastic material

Characteristics: Low ESD, low outgassing properties, ESD performance not affected by molding conditions, semi-crystalline and black color.

The presentation of all these characteristics and properties lead to the conclusion that ESD control is strictly required, the outgassing of the material is low and the ESD performance does not depend on the molding conditions; the material semi-crystalline and it is black with black particles.

Applications :

Semiconductor equipment and tools:

The static control of ESD101 is suitable to protect manufacture equipment and tools within semiconductor industries, specifically to avoid the creation of any electric discharge that can damage electronic components.

Electronic packaging and testing:

In the process of packing or testing of electronic components, ESD 101 materials offer the required electrostatic shield to safeguard the electronic products from potential harm and possible failure.

semiconductor wafer boxes

ESD 101 is used in production of semiconductor wafer boxes in order to eliminate static electricity that can cause damage to sensitive electronic devices and ensure product safety during transportation as well as storage.

For industrial automation equipment

ESD 101 is utilized on anti-static parts like sensor housings or controller housings to guarantee stable operations as well as long life expectancy of the equipment.

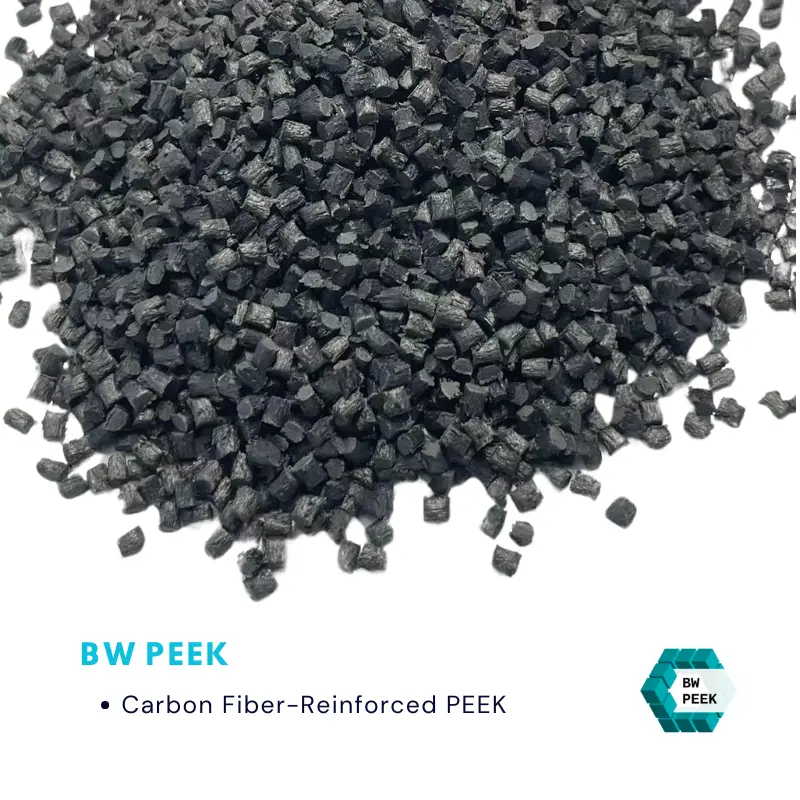

PEEK 90HMF20 is a PEEK material containing 20% high modulus fibers, typically carbon.

Automotive Industry:

Electronic and electrical:

PEEK 90HMF40 is a high-performance PEEK composite material that consists primarily of PEEK 60% pure resin + 40% carbon fiber reinforcement.

Aerospace: PEEK 90HMF40 is used for cable sheathing, connectors, fasteners (Boeing Standard Fasteners, BACS13FV series), and insulating brackets on the Boeing 787 aircraft.

Automotive industry: PEEK 90HMF40 BMW M series engine cover.

Medical devices: PEEK 90HMF40 Surgical implants (hip prostheses) and dental instruments.

Electronic and electrical engineering: High-frequency connectors.