PEEK, or Polyetheretherketone, is a high-performance thermoplastic polymer renowned for its exceptional combination of mechanical properties and chemical resistance. As an engineering plastic, PEEK is frequently chosen for demanding applications across various industries, showcasing its versatility as both a raw plastic material and when fabricated into precision PEEK parts.

Polyetheretherketone (sometimes abbreviated PEEK) is a high-performance thermoplastic polymer of the polyaryletherketone (PAEK) family. Polyether ether ketone is a name that designates the chemical structure of the polymer where the availability of ether and ketone functional groups in the repetitions of the PEEK polymer are emphasized. PEEK is a popular brand called Victrex 152. It is a semi-crystalline, unfilled PEEK plastic material which provides a unique capability due to the combination of mechanical strength, atypical temperature limits, and inertness to chemicals.

The properties of PEEK plastic are what make it a high-performance material. PEEK exhibits outstanding mechanical properties, including high tensile strength, flexural strength, and stiffness, even at elevated temperatures. It demonstrates excellent chemical resistance to a wide range of substances, making it suitable for harsh environments. PEEK also boasts impressive dimensional stability, a low coefficient of friction, and resistance to wear, contributing to its use as PEEK bearing grade.

PEEK plastic is a high-performance material because of its properties. PEEK has excellent mechanical properties such as high tensile strength, flexural strength, and stiffness, both in elevated temperatures. It also happens to exhibit outstanding chemical resistance with most substances, making it good to use with harsh environments. PEEK has also an excellent dimensional stability, low coefficient of friction, and wear resistance, which are contributing factors on it being utilized as PEEK bearing grade.

The special features of PEEK render it priceless in a variety of engineering usage. PEEK plastic is employed in the aerospace business where the supports necessitate high strength, low smoke and poisons gas discharge in an event of fire. The field of oil and gas industries applies PEEK in harsh down hole conditions because of their chemical resistance and also its capability of being resistant to high temperatures. Also, PEEK grades that can be used in food contact are on offer, further increasing its application in the food processing manufacturing area, where it can be exposed to hot water or steam.

PEEK plastic has excellent stiffness and strength combination that proves to be fit in challenging engineering works. PEEK material has the high tensile strength and flexural strength in order to resist high load and stress without deformation or failure. PEEK maintains most of its mechanical properties even under high temperatures, a feature in contrast with other thermoplastic polymers. PEEK machined parts may also be optimized in their stiffness.

The physical properties of PEEK make it a useful performer. The material has low thermal conductivity, making it useful in places where there is a need to have thermal insulation. PEEK is also very thermally stable, with good mechanical properties and dimensional stability over an extended temperature range as well. It is seen that the heat deflection temperature is influenced by grade of PEEK. Pieces made of PEEK remain mechanically tough at higher than 150°C.

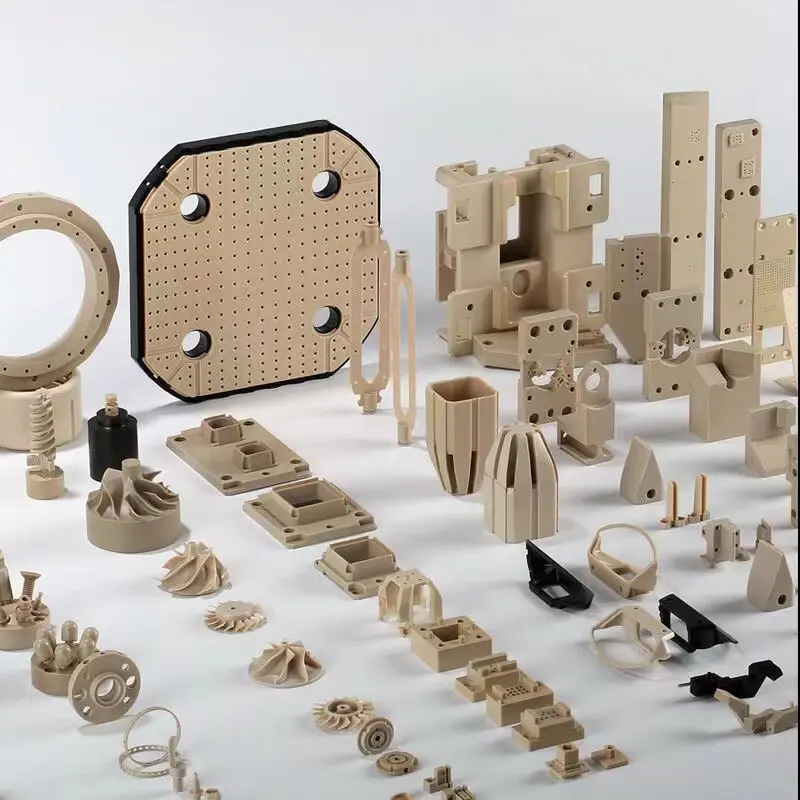

One of the most commonly used techniques that fabricate high quality PEEK components, is CNC machining. Complex geometries and close tolerance tolerances can be produced; therefore, the process can use applications where precision and repeatability are of primary importance. The strengths of PEEK and its abrasive characteristics make it challenging to machine using CNC tools and techniques; however, the end product of PEEK machined parts is characterized by better performance and durability. Victrex PEEK can be easily CNC machined.

PEEK machined parts come with many benefits that compare unfavourably to other components. Its mechanical properties such as high tensile strength and flexural strengths and its stiffness make it easy to ensure that the parts can endure the challenging loading and stress. Strong chemical resistance of PEEK allows it to be used in harsh environments, whereas the dimensional stability allowed retaining shape and size of the part within time and under different temperatures. PEEK bearing grades are optimized with respect to friction.

The high-quality characteristics of Machined PEEK make it applicable in a large variety of industries. PEEK parts find application in the aerospace industry where the materials are utilised on aircraft interiors and also engine parts because the materials have high strength, low smoke, and toxic gases. PEEKs are applied in the medical device manufacturing process in implants and surgical tools because it is biocompatible and sterilizable. Also, the greater mechanical strength of PEEK plastic and resistance to chemicals are important characteristics of components as used in oil and gas.

PEEK injection molding is a high-tech method of manufacturing that involves production of high-tolerance complex shapes generated out of PEEK plastic. It is performed in one step by melting the PEEK component and injecting it at high pressure into the mold cavity. It is because of high-performance qualities of PEEK that to use this method, specific temperatures control and equipment are needed. The molded parts in turn are ejected after cooling and solidification. The type of BWPEEK may influence the effect of PEEK injection. It is able to manufacture parts in a quick and efficient way via the process.

PEEK injection molded parts boast a myriad of benefits, such as flexibility and a high volume production tolerance. The technique enables them to produce complex geometr The mechanical properties of PEEK, which are extraordinary (having high tensile strength and stiffness), are maintained in the injection molded parts, and it is therefore applicable to demanding applications. It is an excellent method of obtaining plastic made components. PEEK injection molding is able to rival CNC machining.

Though there are numerous advantages associated with PEEK injection molding, there are also a number of challenges. PEEK has a high melting point and needs special equipment and careful temperatures control. To produce high-quality molded parts, it is important to take control of the flow of polymer materials as well as to eliminate defects manifesting themselves through voids or warpage of the molded part. Also, the price point of PEEK material is also disproportionately high among other thermoplastics, and so it is relevant to optimize the process with the aim to reduce wastage. PEEK polymer is an excellent plastic material yet one must be careful.

PEEK is unique compared to other high-performance polymers because it has such a remarkable blend of mechanical properties, thermal stability, and chemical resistance. Other polymers might have high performance in specific fields which is true but a more balanced performance has been offered in PEEK thus enhancing its applicability to a broader category of applications. As an illustration, some of the fluoropolymers are difficult to compete with when it comes to their superior chemical resistance but they fail to match PEEK in terms of mechanical strength and stiffness. The grades of PEEK and the unfilled PEEK grades are not the same. It enjoys improved physical characteristics.

When selecting a plastic material for a specific application, both cost and performance must be carefully considered. PEEK is generally more expensive than commodity thermoplastics; however, its superior properties may justify the higher cost in demanding applications. The grade of PEEK also affects the price. Applications include aerospace. A plastic part made of PEEK has great properties. Mechanical strength is great.

Future of PEEK and other high-performance polymer applications seems to be bright as the research and development is going on to improve the properties of the material, lower costs, and increase the applications. The improvement in the polymer chemistry and processing technologies are giving rise to new grades of PEEK that possess superior mechanical behaviour like more ductile and also more impact resistant grades of PEEK. Also, interest in using PEEK in additive manufacturing is increasing, and it opens the possibility to make complex components. The PEEK plastic can, through CNC milling, be used in additive manufacturing.