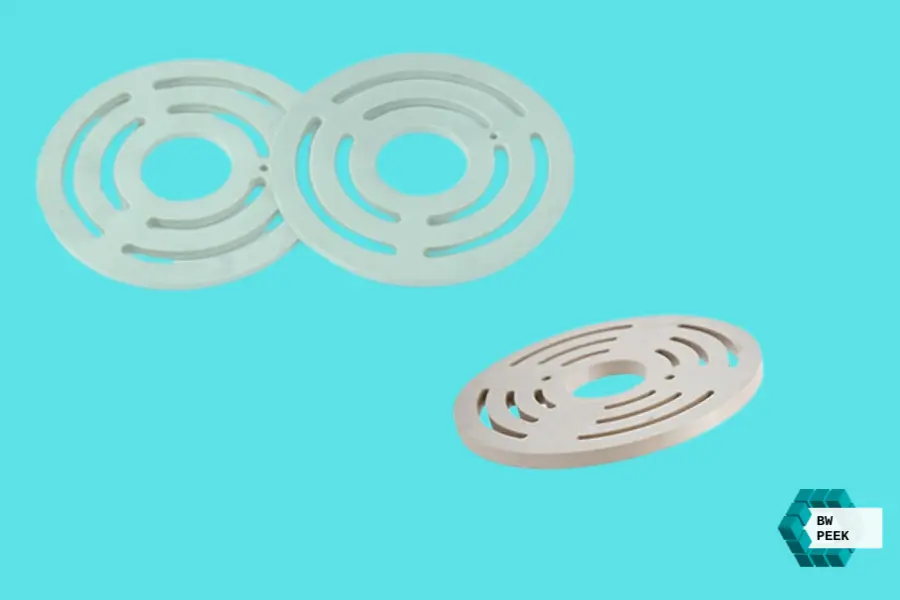

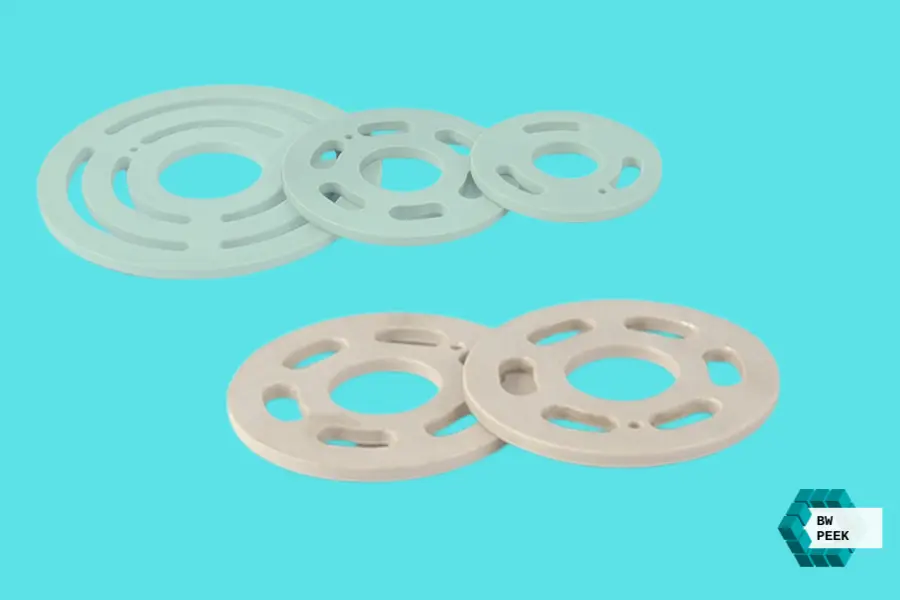

PEEK valve plates for compressors are most suitable for pump compressor valve plates and other high temperature valve seats in nuclear power, petroleum and chemical industries.

Peek valve seats can be machined to your needs, customized PEEK compressor valve plate, our team has extensive design and production experience, especially with CNC machining.

We can develop and design an efficient, fully customized Peek compressor valve plate solution for your team.

At BW PEEK, we specialize in processing Virgin PEEK, Glass Fiber PEEK, and Glass Fiber Reinforced PEEK in various filled compound grades. Thanks to our years of experience solving valve problems, call us for professional and engineered solutions.

| Material | Temperature | Chemical | Mechanical | Wear | Cost | Advantages | Disadvantages |

| PEEK | Up to 260°C | Excellent | High | Very High | High | Superior mechanical properties | High cost |

| Excellent wear and chemical resistance | Difficult to seal due to hardness | ||||||

| Low moisture absorption Flame retardant | |||||||

| CF PEEK | Up to 280°C | Excellent | Very High | Very High | High | Extremely high mechanical strength, stiffness | High cost |

| Excellent wear resistance&low friction. | Potential for increased compared to unfilled PEEK | ||||||

| GF PEEK | Up to 250°C | Excellent | High | High | High | Improved mechanical strength, dimensional | Lower mechanical properties than CF PEEK. |

| resistance compared to unfilled PEEK. | Potential for increased abrasiveness. | ||||||

| PTFE | Up to 260°C | Excellent | Low | Moderate | Moderate | Low friction coefficient | Prone to deformation under high pressure |

| Good chemical resistance | Not suitable for high-load applications | ||||||

| Flexible at low temperatures | |||||||

| POM | Up to 100°C | Good | Moderate | Good | Moderate | Good mechanical properties | Limited chemical compared to PEEK &PTFE |

| Excellent dimensional stability | |||||||

| Easy to machine | |||||||

| UHMW PE | Up to 80°C | Good | Low | Very High | Low | Extremely low friction and excellent wear | Poor high-temperature performance |

| Cost-effective | Limited mechanical strength | ||||||

| Good impact resistance | |||||||

| DELRIN | Up to 100°C | Good | Moderate | Good | Moderate | Good balance of strength and flexibility | Limited chemical resistance |

| Easy to process and machine | Not suitable for high temperatures | ||||||

| Metals | Varies | Varies | Very High | Moderate | High | Exceptional strength and durability | Corrosion issues unless coated |