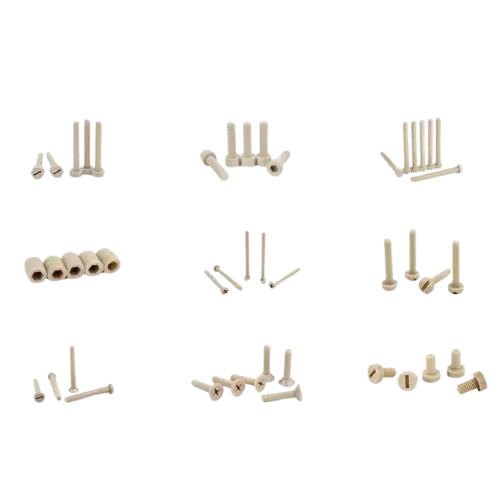

| Screws Name | Metric | L(MM) | Metric | L(MM) |

| PEEK Hex Head Screw size | M4 | 10 | M8 | 40 |

| M4 | 15 | M8 | 50 | |

| M4 | 20 | M10 | 25 | |

| M5 | 8 | M10 | 30 | |

| M5 | 10 | M10 | 40 | |

| M5 | 15 | M10 | 45 | |

| M5 | 20 | M10 | 50 | |

| M5 | 30 | M10 | 65 | |

| M6 | 16 | M12 | 25 | |

| M6 | 20 | M12 | 30 | |

| M6 | 25 | M12 | 35 | |

| M6 | 30 | M12 | 50 | |

| M6 | 40 | M12 | 60 | |

| M8 | 15 | M12 | 65 | |

| M8 | 20 | M12 | 110 | |

| M8 | 25 | M12 | 110 | |

| M8 | 35 |

| Screws Name | Metric | L(MM) | Metric | L(MM) |

| PEEK Hexagon Low Socket Head Cap Screws | M2 | 8 | M6 | 25 |

| M3 | 5 | M6 | 30 | |

| M3 | 20 | M6 | 35 | |

| M4 | 10 | M6 | 40 | |

| M4 | 15 | M6 | 50 | |

| M4 | 20 | M8 | 20 | |

| M5 | 8 | M8 | 25 | |

| M5 | 10 | M8 | 35 | |

| M5 | 15 | M8 | 50 | |

| M5 | 20 | M10 | 25 | |

| M5 | 30 | M10 | 30 | |

| M5 | 35 | M10 | 40 | |

| M6 | 10 | M10 | 45 | |

| M6 | 16 | M12 | 25 | |

| M6 | 20 | M12 | 30 |

| Screws Name | Metric | L(MM) | Metric | L(MM) |

| PEEK PAN Head (Slotted) Screws | M2.5 | 8 | M2.5 | 14 |

| Screws Name | Metric | L(MM) |

| PEEK Socket Head Cap Screws Phillips | M5 | 8 |

| M5 | 9 | |

| M5 | 10 | |

| M5 | 15 | |

| M5 | 20 | |

| M5 | 30 | |

| M6 | 10 | |

| M6 | 16 | |

| M6 | 20 | |

| M6 | 25 | |

| M6 | 40 | |

| M10 | 20 |

| Screws Name | Metric | Le(MM) |

| PEEK Taper Plugs | M5 | 8 |

| M6 | 10 | |

| M8 | 10 | |

| M8 | 15 | |

| M8 | 20 |

| Screws Name | Metric | L(MM) |

| PEEK Flat Head (Slotted) Screws | M5 | 8 |

| M5 | 12 | |

| M5 | 17 | |

| M6 | 10 | |

| M6 | 18 | |

| M6 | 33 | |

| M6 | 43 |

| Screws Name | Metric | L(MM) | Metric | L(MM) |

| PEEK Pan Head (Phillips) Screws | M3 | 10 | M6 | 9 |

| M4 | 10 | M6 | 10 | |

| M4 | 15 | M6 | 16 | |

| M4 | 20 | M6 | 20 | |

| M4 | 30 | M6 | 25 | |

| M4 | 40 | M6 | 30 | |

| M5 | 8 | M6 | 50 | |

| M5 | 10 | M8 | 15 | |

| M5 | 15 | M8 | 25 | |

| M5 | 20 | M8 | 30 | |

| M5 | 30 | M8 | 35 | |

| M5 | 35 | M8 | 45 |

| Screws Name | Metric | L(MM) | Metric | L(MM) |

| PEEK Flat Head (Phillips) Screws | M3 | 10 | M5 | 20 |

| M4 | 15 | M5 | 22 | |

| M5 | 12 | M6 | 50 | |

| M5 | 17 | M8 | 50 |

| Screws Name | Metric | Length(MM) |

| PEEK Slotted Hexagon Head Bolts | M4 | 10 |

| M4 | 15 | |

| M6 | 10 | |

| M6 | 16 | |

| M6 | 20 | |

| M6 | 25 | |

| M6 | 35 | |

| M8 | 20 |

Density: 1.3 g/cm³ (vs. 7.9–8.0 g/cm³ for stainless steel, 4.5 g/cm³ for titanium).

Weight Reduction: 1/6 the weight of stainless steel screws, enabling 15–20% payload optimization in aerospace systems.

Short-Term: Retains >80% tensile strength (90–100 MPa initial, ASTM D638) after 1,000 hours at 260°C.

Thermal Limits: 160°C HDT (1.8 MPa, ISO 75), 343°C melting point (ISO 11357).

Permittivity (ε): 3.2–3.3 at 1 MHz, with <5% variation from -50°C to 250°C.

Dissipation Factor (tanδ): 0.001–0.003 at 1 MHz, stable across frequencies.

Durability: Maintains >90% mechanical properties after 10⁶ Gy gamma irradiation (ASTM D1879).

Nuclear Applications: 10+ years service life in reactor cooling systems, doubling corrosion resistance vs. metal fasteners.

| Property | PEEK Screws | 316L Stainless Steel | Ti-6Al-4V Titanium |

|---|---|---|---|

| Density (g/cm³) | 1.3 | 8.0 | 4.5 |

| Max Operating Temp (°C) | 260 (long-term) | 800 (oxidation failure) | 450 (oxidation failure) |

| Salt Spray Resistance | >5,000 hours | 2,000–3,000 hours | 3,000–4,000 hours |

| Radiation Tolerance | 1×10⁶ Gy | 1×10⁴ Gy (embrittlement) | 5×10⁴ Gy (surface decay) |

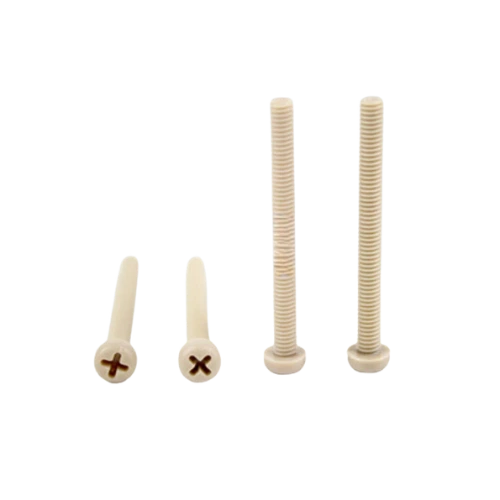

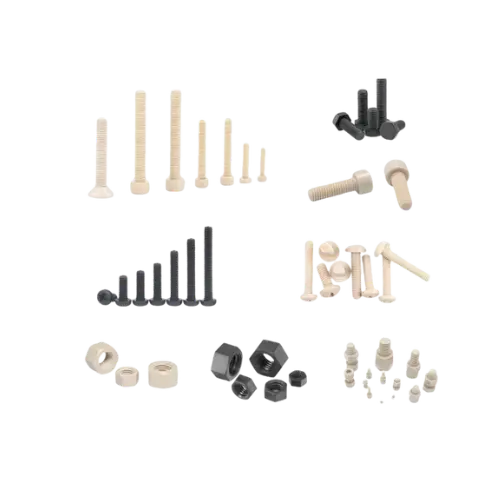

Beige

100 screws per pack

At BWPEEK, you can select PEEK screws tailored to your requirements. Our PEEK screw range features extensive variety, comprehensive sizing, superior quality, corrosion resistance, and lightweight properties. Covering nearly all models from M2 to M10, we maintain long-term stock availability to fulfil immediate dispatch needs. Additionally, we accommodate custom screw specifications—from CNC machining to injection moulding and grinding—all are feasible. Contact us promptly.

Our email address: sales@peekmaterials.com

BWPEEK screws are commonly employed in wet processing equipment to secure components.

Within photovoltaic wet processing, PEEK screws help ensure reliable equipment operation under demanding conditions, supporting efficient solar cell production.

Yes, PEEK (Polyether Ether Ketone) fasteners are quite appropriate in most industrial applications especially where other metal or nylon fasteners might fail because of corrosion, high temperature, or exposure to chemicals. This thermoplastic substance has an outstanding mechanical strength, thermal stability up to 260 °C (500 °F), low friction and wear resistance that make it suitable in aerospace, oil and gas, semiconductor manufacture and chemical processing industries. These also have good insulation properties that shield against electrical shocks in electronic systems and they are non-conductive, which is advantageous in an electromagnetic-sensitive environment.