As electric vehicle (EV) technology and high-voltage applications continue to evolve, the demand for materials that can withstand extreme electrical and environmental conditions has never been greater. One such material leading this transformation is PEEK (Polyether ether ketone) wire. Known for its exceptional electrical insulation, thermal stability, and mechanical durability, PEEK wire is increasingly replacing traditional enameled copper wire, particularly in high-voltage drive systems ranging from 800V to 1200V.

The voltage resistance of PEEK wire varies with diameter:

0.10 mm diameter wire – suitable for applications requiring insulation from hundreds to thousands of volts

0.50 mm diameter wire – handles over 5,000 volts

1.00 mm and larger – exceeds 10,000 volts, offering robust protection for heavy-duty applications

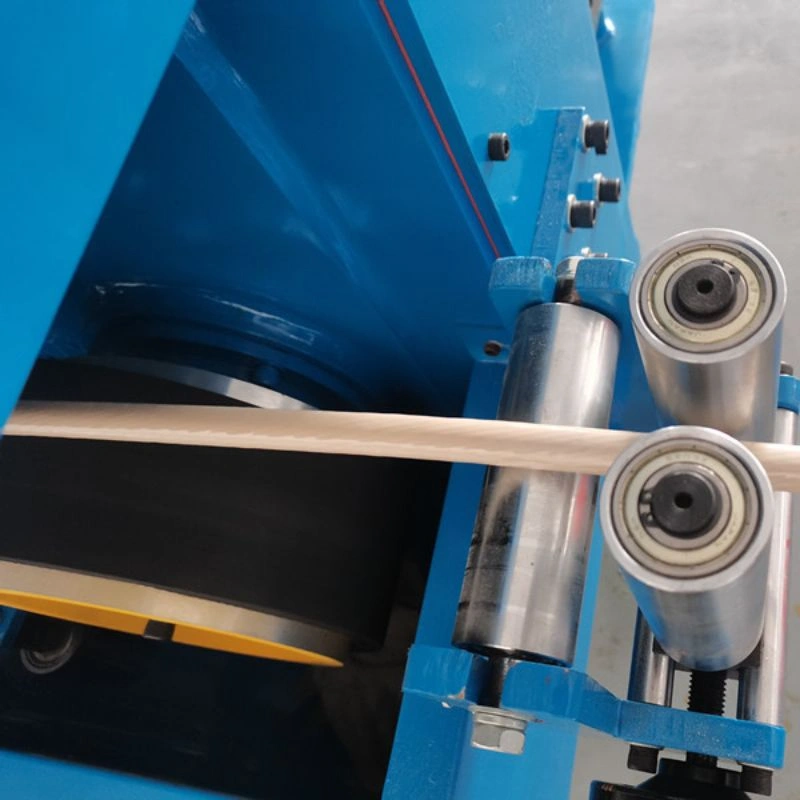

PEEK extruded flat wire offers a simpler manufacturing process and delivers greater product stability. Unlike traditional wires, it doesn't require multiple layers of coating or baking to achieve excellent pressure resistance. Additionally, it can endure repeated bending without cracking, making it ideal for hairpin processing in motor windings.

With years of expertise in developing and manufacturing motor magnet wires, BW Material Company has successfully engineered PEEK insulated wires through the dedicated efforts of its R&D and technical teams. These wires offer high-temperature resistance, superior flame retardancy, enhanced high-voltage performance, radiation resistance, and outstanding mechanical strength.

The voltage resistance of PEEK wire depends on its diameter:

| Property | Specification |

| Electrical Insulation | Excellent |

| Dielectric Strength | 20–24 kV/mm |

| Tensile Strength | High |

| Thermal Stability | Up to 240°C |

| Glass Transition Temperature (Tg) | ~143°C |

| Operating Temperature Range | -40°C to 130°C |

| Chemical Resistance | Outstanding against ATF, fuels, and solvents |

| Thermal Conductivity | 0.35 W/m·K (higher than aramid paper at 0.1 W/m·K) |

| VOC Emissions | None – environmentally safe |

| Resin Absorption | Fast, due to low viscosity during processing |

| Expansion Coefficient | 48 ppm (low temp) to 208 ppm (high temp) |

| No | W | T | T | T | T | T | T | T | T | T | T | T | T | T | T | T | T | T | T | T | T |

| 1 | 0.3 | 0.2 | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / |

| 2 | 0.5 | 0.2 | 0.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / |

| 3 | 1 | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | / | / | / | / | / | / | / | / | / | / | / | / | / |

| 4 | 2 | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | / | / | / | / | / | / | / | / | / | / | / | / | / |

| 5 | 3 | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | / | / | / | / | / | / | / | / | / | / |

| 6 | 4 | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | / | / | / | / | / | / |

| 7 | 5 | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | / | / | / |

| 8 | 6 | 0.2 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 |

| 9 | 7 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / |

| 10 | 8 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / |

| 11 | 9 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / |

| 12 | 10 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / |

| 13 | 12 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / |

| 14 | 14 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / |

| 15 | 16 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / | / |

| 16 | 18 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / | / |

| 17 | 20 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / | / |

| 18 | 23 | 0.75 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / | / |

| 19 | 25 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 4.75 | 5 | / | / | / |

PEEK insulated wires are transforming how industries design high-performance systems. Key application sectors include:

Electric vehicles (EVs) – for drive motors, inverters, and battery systems

High-voltage motors and generators – particularly flat winding technologies

Aerospace and defense systems – where lightweight, high-durability cables are critical

Industrial robotics – operating under continuous thermal and mechanical load

Medical and diagnostic equipment – where precision and insulation reliability are crucial

Width Range: 0.30 mm to 25.00 mm

Thickness Range: 0.20 mm to 5.00 mm

Width-to-Thickness Ratio: Between 1:1 and 1:30

Enamel Thickness Grades (Pre-side Insulation Thickness):

Grade 0: Over 150 µm — Enamel Thickness: 0.15 mm | BDV: >20,000 V | PDIV: >2,100 V

Grade 1: 120–150 µm — Enamel Thickness: 0.120–0.150 mm | BDV: >15,000 V | PDIV: >1,800 V

Grade 2: 90–120 µm — Enamel Thickness: 0.090–0.120 mm | BDV: >12,000 V | PDIV: >1,600 V

Grade 3: 60–90 µm — Enamel Thickness: 0.060–0.090 mm | BDV: >9,000 V | PDIV: >1,400 V

Grade 4: 30–60 µm — Enamel Thickness: 0.030–0.060 mm | BDV: >6,000 V | PDIV: >1,200 V

Diameter Range: Ø0.65 mm to Ø4.20 mm

Enamel Thickness Grades (Pre-side Insulation Thickness):

Grade 0: Over 150 µm — Enamel Thickness: 0.15 mm | BDV: >20,000 V | PDIV: >2,100 V

Grade 1: 120–150 µm — Enamel Thickness: 0.120–0.150 mm | BDV: >15,000 V | PDIV: >1,800 V

Grade 2: 90–120 µm — Enamel Thickness: 0.090–0.120 mm | BDV: >12,000 V | PDIV: >1,600 V

Note:

BDV (Breakdown Voltage) indicates the maximum voltage the insulation can withstand before breaking down.

PDIV (Partial Discharge Inception Voltage) refers to the minimum voltage at which partial discharge begins to occur.