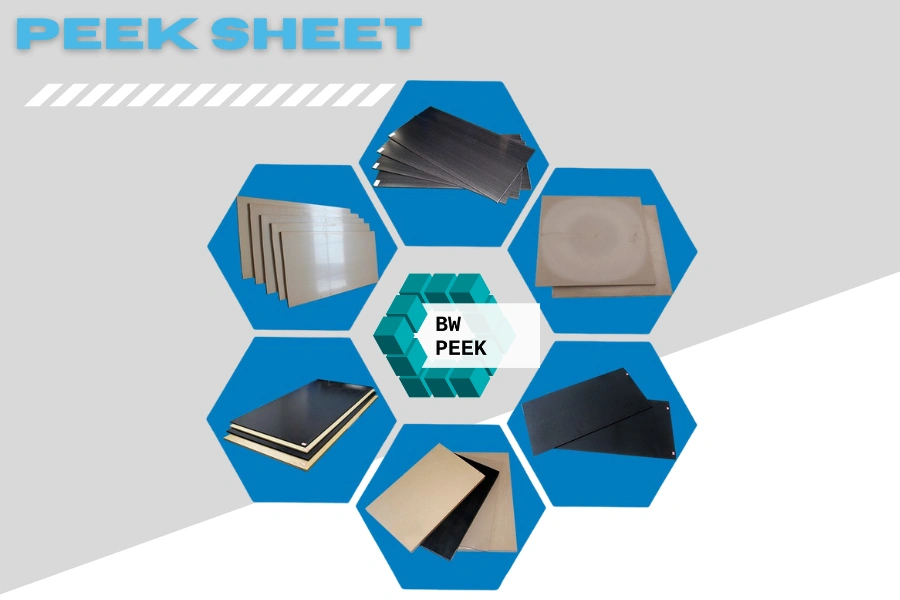

peek 450g sheet Is extruded from PEEK pure resin, which has good toughness and strong impact resistance.

This is manufactured from pure polyether ether ketone resin, which is the toughest and most impact resistant of all PEEK grades. Pure PEEK can be sterilized using convenient sterilization methods (steam, dry heat, ethanol, and Y-rays), and the raw material components used in the manufacture of PEEK comply with European Union and U.S. FDA regulations on food safety.

PEEK 450Gl30 This material is filled with 30% glass fiber reinforced grade plastic, than PEEK has better rigidity and creep resistance, as well as better dimensional stability, the manufacture of structural parts is ideal. At high temperatures for a long time to withstand fixed loads.

The material is filled with 30% carbon fiber reinforced, than PEEK-450CA30 has better mechanical properties (higher modulus of elasticity, mechanical strength and creep) and more wear-resistant, but also add carbon fiber reinforced plastic than unreinforced PEEK plastic has 3.5 times the thermal conductivity faster heat dissipation from the bearing surface.

ESD PEEK rod can a avoid the harm of voltage discharge to people or objects. Based on static electricity control and permanent dissipation of static charge, this kind of plastic can provide high-level safety for application fields.

AST PEEK rod is based on PEEK raw material which is mixed with carbon fiber. carbon black, metal fber, metal powder, permanent antistatic masterbatch etc. , so as to achieve the functions of conductivity and electromagnetic interference shielding.

Beige, black

+-2mm

PEEK sheets made by a continuous extrusion method typically have lengths of 600 and 3000 mm, although they can also be trimmed to fit specific customer requirements.

| T*W*L(mm) | Weight(kg) | T*W*L(mm) | Weight(kg) |

|---|---|---|---|

| 1*610*1220 | 1.1 | 25*610*1220 | 26.33 |

| 2*610*1220 | 2.11 | 30*610*1220 | 31.9 |

| 3*610*1220 | 3.72 | 35*610*1220 | 38.48 |

| 4*610*1220 | 5.03 | 40*610*1220 | 41.5 |

| 5*610*1220 | 5.068 | 45*610*1220 | 46.23 |

| 6*610*1220 | 6.654 | 50*610*1220 | 53.35 |

| 8*610*1220 | 8.62 | 60*610*1220 | 62.3 |

| 10*610*1220 | 10.85 | 100*610*1220 | 102.5 |

| 12*610*1220 | 12.55 | 120*610*1220 | 122.6 |

| 15*610*1220 | 15.85 | 150*610*1220 | 152.71 |

| 20*610*1220 | 21.725 | ||

| T:Thicness | W:width | L:long |