Material Integrity Strategies: Navigating PEEK Authenticity and Manufacturing Reliability

In sectors where failure is not an option—such as semiconductor fabrication and medical device manufacturing—the authenticity of PEEK (Polyetheretherketone) is not just a technical preference; it is a prerequisite for operational safety.

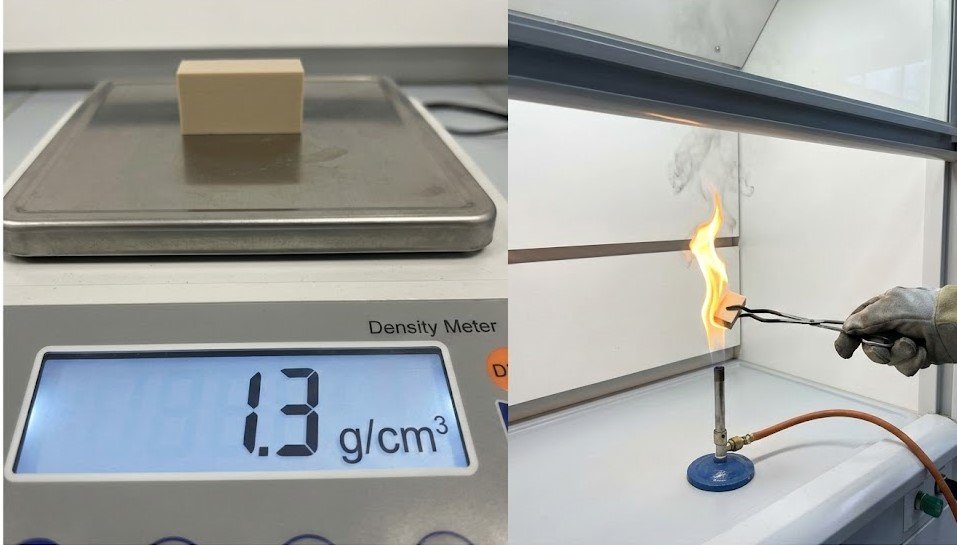

Figure 1: PEEK plastic density measurement and combustion flame color test. The left figure shows that the standard density of PEEK is approximately 1.3 g/cm³; the right figure shows the characteristic yellow-orange flame of PEEK when burning.

The prevalence of substandard or adulterated materials in the global market has significantly escalated project risks. While empirical verification methods, such as density checks (typically ~1.3 g/cm³), flame observation (orange-hued flames with distinct phenolic emissions), or sulfuric acid resistance tests, offer a baseline reference, they remain merely diagnostic.

A more robust engineering strategy involves transitioning from “post-hoc verification” to “proactive supply chain and process governance.” This necessitates a critical evaluation of manufacturing methodologies—Subtractive Machining versus Injection Molding—and their respective roles in ensuring material consistency.

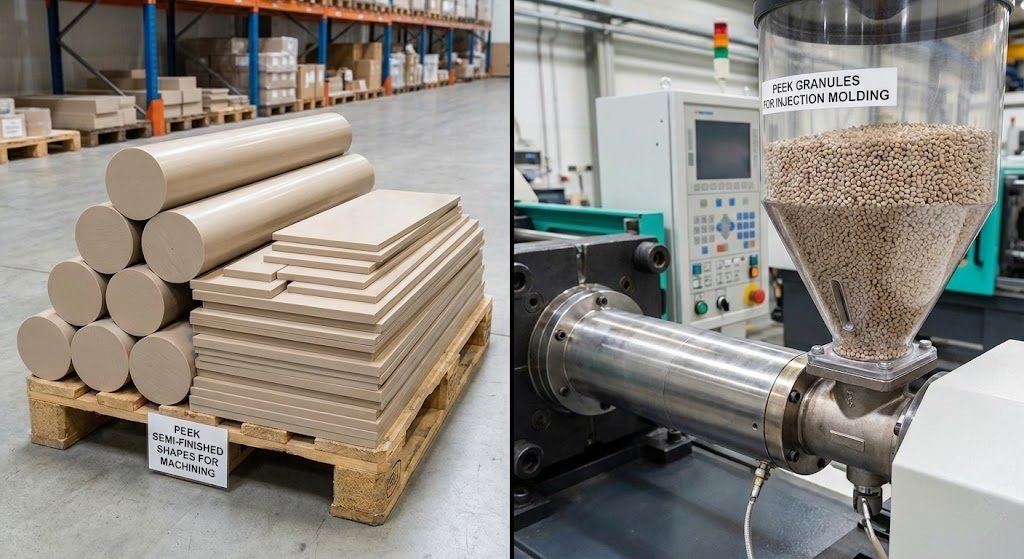

Machining derives components from semi-finished stocks, such as rods and plates. While this path offers unmatched flexibility for rapid prototyping and low-volume spares, its reliability is fundamentally bottlenecked by the integrity of the purchased stock.

Figure 2: Comparison of PEEK profiles for machining (left) and PEEK granules for injection molding (right). Different manufacturing paths determine different material control models.

Any structural contamination or chemical inconsistency within the billet is often invisible during the cutting process. Consequently, precision machining cannot compensate for compromised raw material. This reliance places an immense burden of trust on the material supplier and necessitates exhaustive, batch-level validation—a process that presents significant quality control challenges during the transition to volume production.

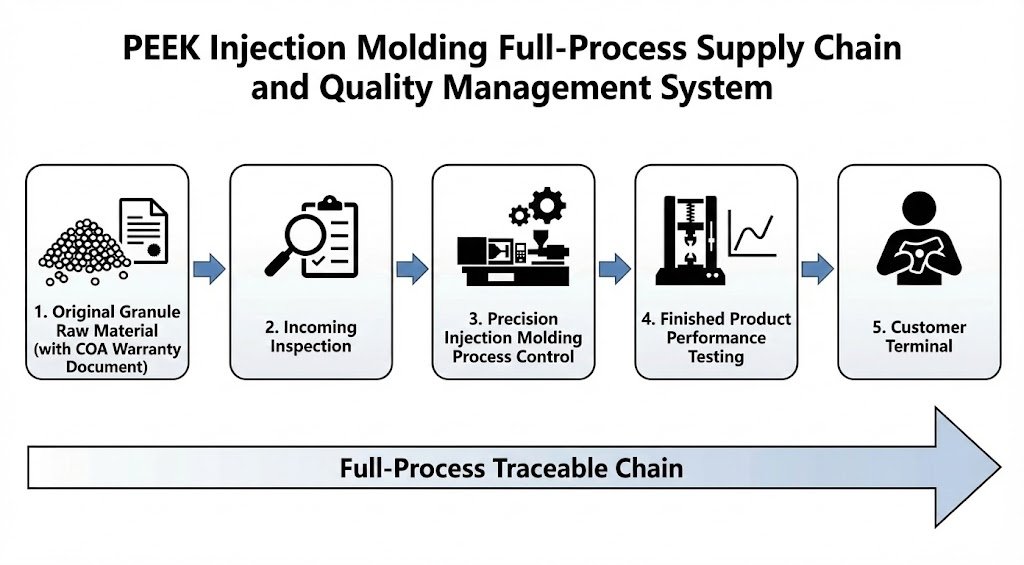

In contrast, a systematic injection molding framework provides a deeper, highly traceable model for material management. Professional PEEK processing does not begin at the machine; it starts with rigorous resin qualification and the verification of Certificates of Analysis (COA).

More importantly, the injection process itself functions as a “performance litmus test”. PEEK possesses an exceptionally narrow thermal processing window; its rheological (flow) and crystallization characteristics only stabilize under specific, high-precision parameters. Adulterated or inferior resins typically fail to meet these rheological thresholds, manifesting as discernible defects—such as short shots, surface irregularities, or significant mechanical degradation—during the pilot stage. Thus, a mature molding protocol serves as an inherent technical barrier against counterfeit materials.

Figure 3: PEEK injection molding end-to-end supply chain and quality management system. A traceable chain from raw materials to finished products is key to ensuring material authenticity.

From an operational standpoint, high-tier injection molding providers tend to align with verified, long-term material sources to maintain batch-to-batch stability. In sophisticated manufacturing hubs like Dongguan, reputable PEEK specialists leverage integrated solutions that encompass material grade selection, supplier auditing, and production stability. This ecosystem-driven approach effectively transforms the uncertainty of material authenticity into a transparent, manageable workflow.

While machining remains indispensable for R&D trials and non-standard large parts, Injection Molding provides a more resilient path for high-reliability, design-frozen production.

The most effective safeguard against PEEK authenticity risks is not the reliance on end-user diagnostic tests, but the selection of a manufacturing partner with internalized material governance. A high-performance PEEK solution is ultimately defined by a trusted chain of custody—from the raw granule to the finished, mission-ready component.