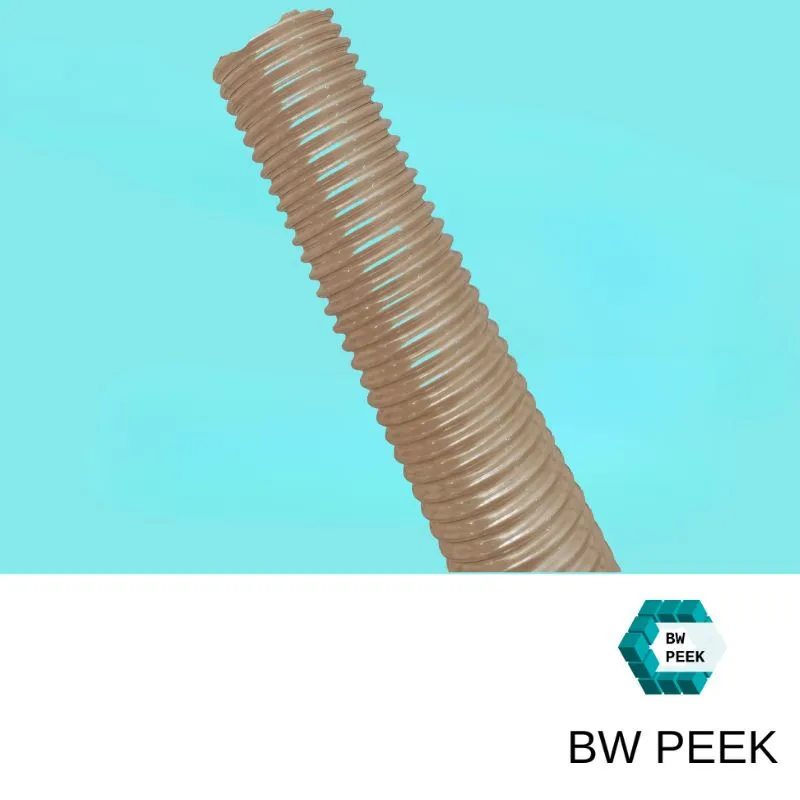

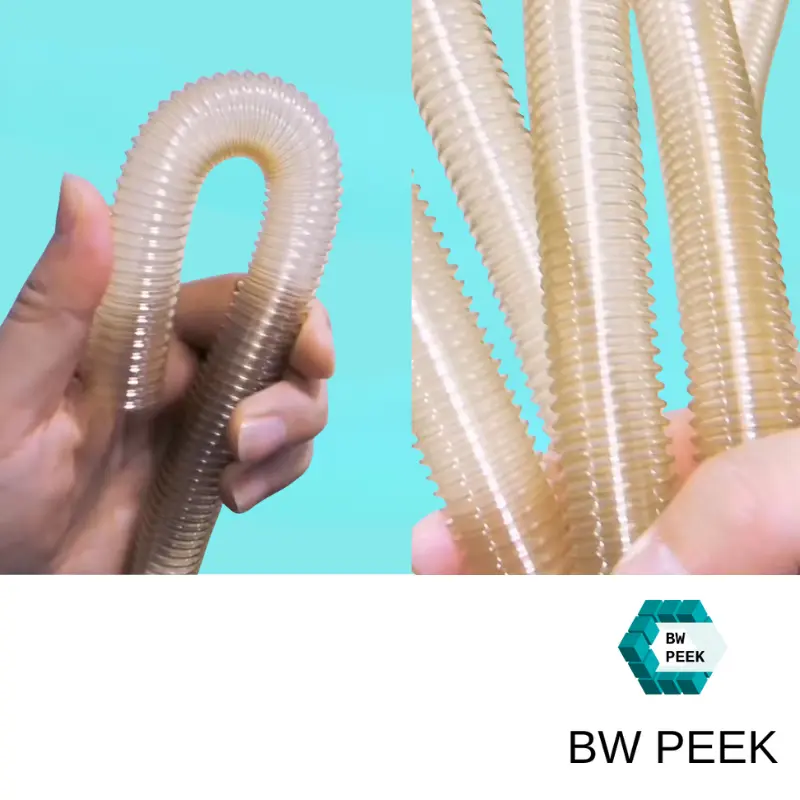

PEEK bellows are superior to be used in designs that require high temperatures of strong alkalis or organic solvents like in diaphragm pumps or metering lines in a chemical plant. Their corrosion resistance and strength against fatigue make them an alternative of choice in case PTFE or the metal substitutes are not sufficient.

PEEK bellows would be a good solution in semiconductor wet-bench systems where chemical purity and particle generation are paramount concerns. Their outgassing is low and the modulus is high and is used to maintain system integrity in repetitive motion.

Mass spectrometers or other analytical instruments In the case of vacuum chambers, PEEK bellows can be used as a flexible protective element, although the designers need to verify that it can be used in a vacuum, and outgassing limits and the necessity of bake-out must be taken into account.

PEEK bellows with the right combination of grades and processing can be utilised in a medical fluidics, sterilizable equipment and other controlled conditions, particularly when metal parts are inappropriate or too heavy, and PTFE is not strong enough.

Additionally, it may be employed as cable protection conduits in corrosive environments, vacuum and pressure piping within high-temperature systems, pharmaceutical and food processing equipment requiring cleanliness and durability, fluid management systems in the automotive and aerospace industries, and as feed and discharge pipes for tankers, storage tanks, vessels, and reactors. It may serve as a replacement for piping materials such as graphite, ceramics, and glass, which possess lower mechanical strength.

PEEK has greater mechanical strength and rigidity (which is advantageous in dynamic motion and fatigue resistance). PTFE is the best in terms of chemical inertness (most particularly strong acids). When chemical environment is very aggressive, then PTFE can be used, when motion, strength and durability is of concern then PEEK can be a better choice.

In most datasheets, PEEK is resistant to sodium hydroxide (e.g., 10-50% NaOH at 100 of lower) at 100°C of less. But above 10% concentrated sulfuric acid, its performance is not so much reliable and special testing or other material might be required.

PEEK may be used in vacuum systems, but polymers generally have higher outgassing and permeation than metals. For UHV applications, you should verify bake-out capability, outgassing rates and whether a metal bellows is required.

Typical options include machining (flexible for custom), injection/compression molding (suitable for volume production) and dip-molding (good for thin-walled or complex geometry components).

| OD(INCH) | OD(MM) | ID +/- INCH | OD +/- MM | wall-T(INCH) | wall-T(MM) |

| 3 /16 | 4.76 | 0.182-0.192 | 4.62-4.88 | 0.005 | 0.127 |

| 1 /4 | 6.35 | 0.245-0.255 | 6.22-6.48 | 0.007 | 0.178 |

| 3 /8 | 9.53 | 0.370-0.380 | 9.40-9.65 | 0.01 | 0.254 |

| 1 /2 | 12.7 | 0.493-0.507 | 12.5-12.9 | 0.012 | 0.305 |

| 5 /8 | 15.9 | 0.618-0.632 | 15.9-16.1 | 0.012 | 0.305 |

| 3 /4 | 19.1 | 0.740-0.760 | 18.8-19.3 | 0.015 | 0.381 |

| 7 /8 | 22.2 | 0.860-0.890 | 21.8-22.6 | 0.015 | 0.381 |

| 1.0 | 25.4 | 0.980-1.02 | 24.9-25.9 | 0.02 | 0.508 |