Polyvinylidene fluoride (often referred to as PVDF), is a high regulation fluoropolymer material that is known because of its very high attributes as well as the range of usability. The outstanding feature of this type of thermoplastic material is the high level of chemical resistance, high mechanical strength, which is accompanied by superior performance in various industries. The peculiarities of PVDF and its ability to combine properties and processability composites it as the optimal solution in harsh environments.

PVDF or polyvinylidene fluoride is a fluoropolymer which is a product of the repeating units of vinylidene fluoride. This plastic has a chemical structure that gives it a very high chemical resistance, and consequently, it will not dissolve in numerous solvents. This stability and degradation resistance of PVDF is caused by the presence of fluorine atoms. This property of the polymer is crucial in applications where durability and longevity are needed.

PVDF comes in a variety of forms. Some typical forms and their applications are summarised in the table below: They are determined by the particular use of cases.

| Form | Description |

|---|---|

| PVDF Resin | Base material for producing products like pipes, films, and membranes. |

| PVDF Coating | Applied to surfaces to provide chemical resistance and UV protection. |

To make PVDF, monomers of the vinylidene fluoride is normally polymerized. This includes the reaction to give a semi-crystalline thermoplastic fluoropolymer in its raw form, characterised by high chemical resistance. PVDF crystallinity can be manipulated during its production, which also affects thermal and mechanical properties of PVDF.

PVDF has a distinct number of both physical and chemical properties that contribute to its high-performance. In particular, it portrays some predominant strengths such as:

These features render PVDF to withstand unfavourable environments.

PVDF resin leads to many benefits such as a high level of mechanical strength, learns more readily, is highly resistant to chemicals. Being a thermoplastic fluoropolymer, PVDF resin can be shaped in different shapes and forms and as such it enjoys a wide variety of applications. PVDF resin has high stability and temperature which means the capacities of the material last long time under severe conditions. The application of PVDF resin is popular in several industries.

Although PVDF coating has great chemical resistance and UV protective nature, it is limited to some extent. PVDF coating is not often coated directly and so the application may be more complicated in comparison to other coating materials. Also, the price of PVDF film can be more expensive than other models. Nevertheless, PVDF coating has other advantages including durability over long term.

The great importance of PVDF is a high chemical resistance that benefits the chemical and pharmaceutical industries nearly to an incredible extent. PVDF pipes and PVDF products have widely found application in chemical processing equipment to expedite the transportation of corrosive fluid thus ensuring wear and tear as well as reducing the chances of contamination. The quickensil and torriculant nature of the PVDF material fits best in the coating of tanks and vessels due to its non-solvability and its being an electrically effective material that will act as one of the solid defences against corrosive compound. The structural integrity and durability of equipment in this high-stress industrial environment is assured by the usage of PVDF. PVDF polymer is resistant to a variety of chemicals.

PVDF membrane technology has transformed the processes of water treatment and filtration. PVDF offers high mechanical resilience and chemical resistance hence rendering it a perfect fit in fabricating membranes in water purification and desalination. A higher PVDF membrane has better rates of flux and resistance to fouling which sustain the efficiency and life span of the filtration systems. These membranes are systematically able to remove a broad spectrum of pollutants to render water drinkable. Application of PVDF increases durability of water and treatment solutions.

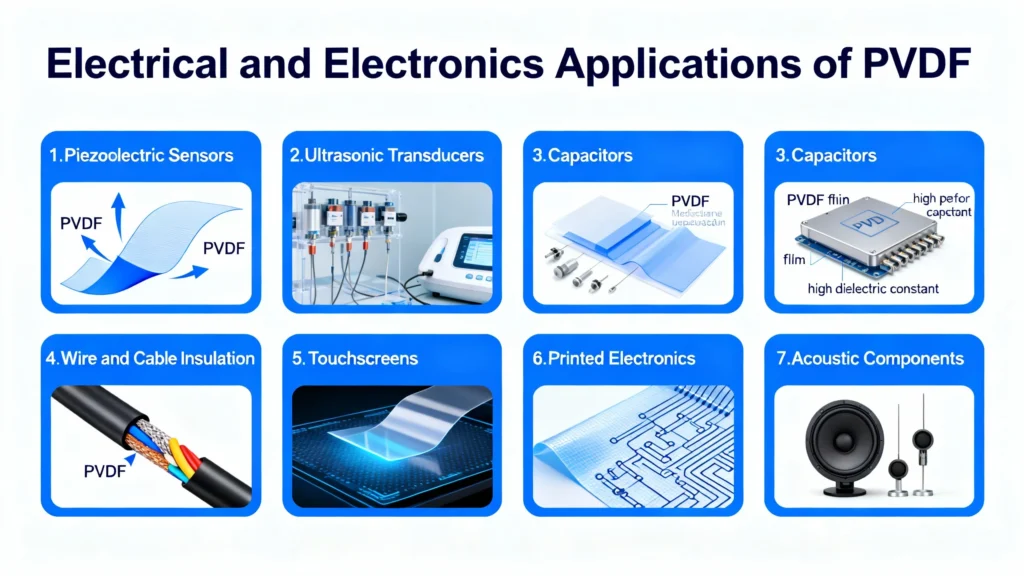

PVDF is used in a variety of electrical and electronics and this is because of its dielectric characteristics and its capability to withstand high temperature. PVDF films are used as insulators in capacitors and printed circuits boards to provide a reliable way of operation and reducing signal loss. It utilises the piezoelectric capabilities of PVDFs in sensor and actuator devices, allowing precise control and responsiveness within electronic devices. Flexible PVDF is being used more in wearable electronics and in flexible displays with new source of opportunities to create new designs. Its structure, which renders it very popular, is the nature of the polymer.

PVDF finds application in the building and architectural industry because of its high weatherability and UV resistance. PVDF coating is something that would be used on building faces, roofing material and architectural panels giving enhancements long against sunlight and other environmental pollutants. Such a coating of PVDF will improve the visual effect and prolong the durability of buildings, reducing the cost of maintenance, and guaranteeing prolonged functionality. PVDF is used to enhance durability of the structure in terms of wear. The coating averts radiation damage.

Polyvinylidene fluoride (PVDF) is a key material in renewable energy technologies, primarily utilised in solar panels and energy storage equipment.Solar modules are available in PVDF film designed to wrap up the sensitive photovoltaic cells to shield them against moisture and other elements that can cause the breakdown. PVDF polymer is favoured by the good chemical stability and temperature resistance of high temperatures, which are the requirements of ensuring long-term performance of solar power generation and boil stability and reliability. There is also a development of PVDF copolymers as binders at lithium-ion battery electrodes increasing their energy density and cycle life. The sector uses a lot of PVDF.

High-performance materials of outstanding qualities are required in the medical and aerospace industries. PVDF can fulfil these needs, and it is biocompatible, chemically resistant, and radiation-stable. PVDF membranes have been used in drug delivery systems and medical filtration devices and guarantee purity and the ability to release chemicals controllably. PVDF coating is used to shield aircraft and spacecraft components to a corrosive environment and extreme temperatures in aerospace applications that ensure safety and reliability. The nature of the polymer offers a solid service.

The applications of PVDF are further widening their applications in 2025. The sensing and energy harvesting devices are becoming innovative due to the development of PVDF copolymers that possess greater piezoelectric characteristics. The additive manufacturing method can be used to produce multi-functional PVDF structures of complex forms. Also, the growing interest of sustainability is encouraging the creation of bio-based PVDF substances and the recycling systems, minimising the environmental impact of this all-round thermoplastic fluoropolymer. New types of PVDF will be on sale.

Sustainability change in the manufacturing of PVDF is becoming significant due to increased environmental issues. The industry is exploring vigorously bio-based substitutes to the traditional PVDF with the view of minimising its dependence to fossil fuels. They are also developing recycling technologies to recycle and reuse PVDF in end-of-life products as part of reducing the amount of waste generated and developing a circular economy. These are in line with increased need of environmentally friendly processes and materials, leading to innovation in PVDF production. Liability on use of PVDF piles up.

The technology of PVDF membrane is fixing to revolutionise different industries like water treatment, pharmaceuticals, and energy storage. The production of improved PVDF copolymers with improved chemical resistance and mechanical strength is facilitating the establishment of high-performance membrane with increased flux rate and fouling resistance. PVDF membranes featuring customised apertures and characteristics are also being manufactured using additive manufacturing techniques to optimise their performance in specific applications. This development is pushing the limits of the PVDF membrane technology.

The industry of PVDF resin and coating is made up of several market leaders who influence innovation and trends in the market. Such companies have broad experience in the chemistry and production of PVDF polymer, which allowed them to prepare PVDF of various properties according to their needs. They spend a lot of money on research and development coming up with new grades of PVDF with characterised performance natures as well as experimenting with new uses in fields like renewable energy, electric cars and suchlike. They are dedicated to quality and innovation, which makes them the market leaders.

PVDF industry has several challenges among them being the high price of raw materials, environmental effect on manufacturing process as well as competition which arise with other manufacturing materials. The cost of any type of feedstock fluoropolymer can be extremely variable and can affect the profitability of PVDF production. This is because the environment issue needs to be addressed by coming up with more sustainable technology in production and encouraging recycle systems. The industry should also distinguish PVDF through emphasis on its special set of attributes and its ability to be processed as compete with other high-performance materials.

Polyvinylidene fluoride is denoted as PVDF, and the reason behind its high usage in different industries is because it has excellent features. It is also highly resistant to chemicals, thus it is practical when dealing with compounds that are corrosive like use in chemical processes plants. PVDF membranes are also used in the treatment of water due to their stability and the capacity of filtering water impurities. As part of electronics, PVDF films are insulators. In building construction, the PVDF is also used as a barrier to UV radiation, and weather conditions. It is also made use of in lithium-ion batteries.

Generally, PVDF can be deemed to be safe in the areas that it is to be used, so long as it is handled and processed properly. PVDF is a fluoropolymer and thermoplastic material with lower chemical instability such that the chances of vaporising toxic substances to the environment are reduced. Biocompatible grades of PVDF are applied in medicine. Nevertheless, there is need to take precautions during processing to prevent fumes inhalation. The aim of this should be to ensure correct disposal procedures are undertaken in order to ensure that the environment is not affected in any possible manner. The properties allow it to be a safe polymer selection.

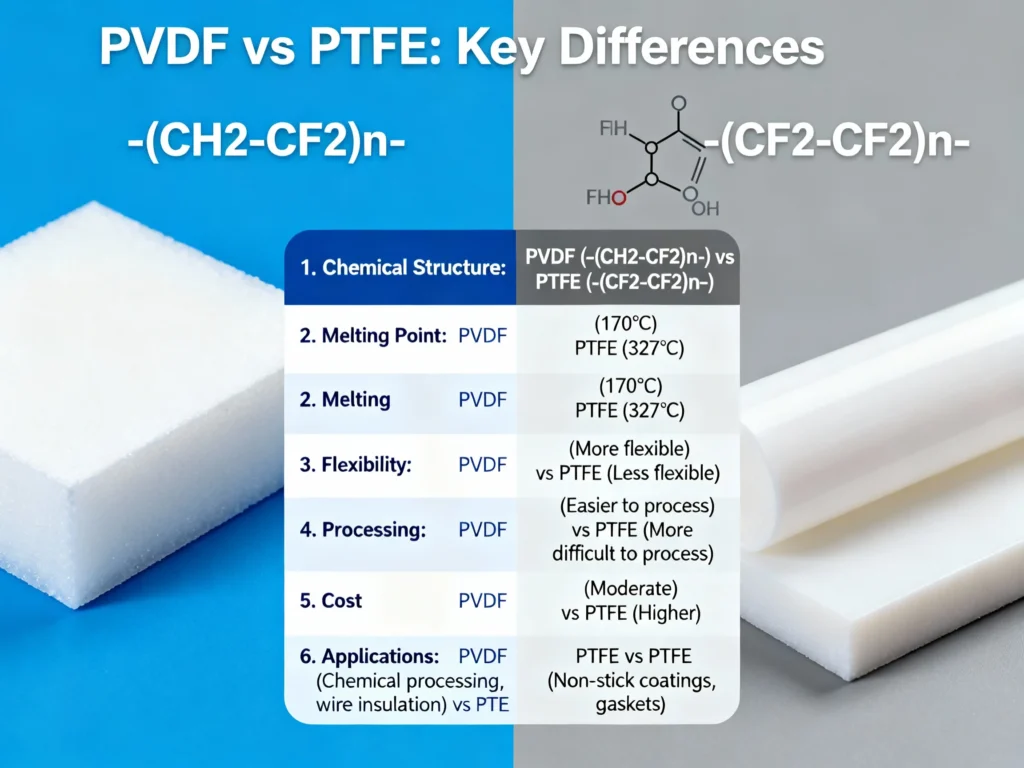

Although both PVDF and PTFE (polytetrafluoroethylene) are fluoropolymers, they differ in several key aspects. The table below summarises some of the principal distinctions:

| Property | PVDF | PTFE |

|---|---|---|

| Chemical Resistance, Mechanical Strength, Ease of Processing | Better Balance | N/A |

| High Temperature Resistance | N/A | Superior |

| Piezoelectric properties | Yes | No |

| Crystalline Structure | Semi-crystalline | N/A |

PVDF can be processed by conventional melt-processing methods, whereas PTFE requires specialised techniques. PTFE also exhibits a lower coefficient of friction than PVDF.

PVDF plastic price may change with different factors such as grades of the material and growth, quantity of the material and its seller. As a rule, PVDF is a more expensive material compared to such commodity plastics as polyethylene or polypropylene because it has high-performance characteristics and complex production methods. Nevertheless, its more demanding applications can justify the initial premium cost through PVDF’s long-term advantages, including its durability and chemical inertness.It is cost effective due to factors such as radiation resistance.

PVDF is itself a highly resistant material to moisture and water absorption and thus is an effectively waterproof material. Its chemical composition and hydrophobic nature will avoid water entering the plastic so that its integrity and performance characteristics in wet conditions are in place. This offers PVDF to be used in situations where either durability or reliability is needed in humid or submerged environments. High resistance with PVDF is emphasised through water treatment.Its insolubility and electrical properties render it suitable for use with a wide range of chemicals.

Density of PVDF is usually 1.74 to 1.78 g/cm 3 which varies with the grade and crystallinity. This is more than many other thermoplastics and this becomes evident regarding the weight of the material PVDF weighs more per unit volume. Weight is also another factor that is considered in the density of PVDF as some applications may need it be lightweight, automotive or aerospace parts. The density measurement aids the calculation of products manufactured by PVDF and in engineering which may need some particular properties.

The density of PVDF typically ranges from 1.74 to 1.78 g/cm³, depending on the grade and crystallinity. This density is higher than that of many other thermoplastics, reflecting PVDF’s greater mass per unit volume. The density of PVDF is an important consideration in applications where weight is a factor, such as in automotive or aerospace components. Knowing the density helps in calculations for PVDF products and engineering applications requiring specific characteristics.

To answer the question of whether PVDF plastic is appropriate in your project, it will be wise to take into consideration some physical and chemical characteristics, strengths and shortcomings. PVDF can be an excellent choice in the applications that require great chemical resistance, high mechanical strength, and extended life in severe conditions. Nevertheless, cost is more favourable than other plastics but not effectiveness, which is more considered. Piezoelectric characteristics, or radiation resistance should be taken into account as well. Determine the special needs and characteristics.