REACH, ROHS, and biocompatibility reports are available.

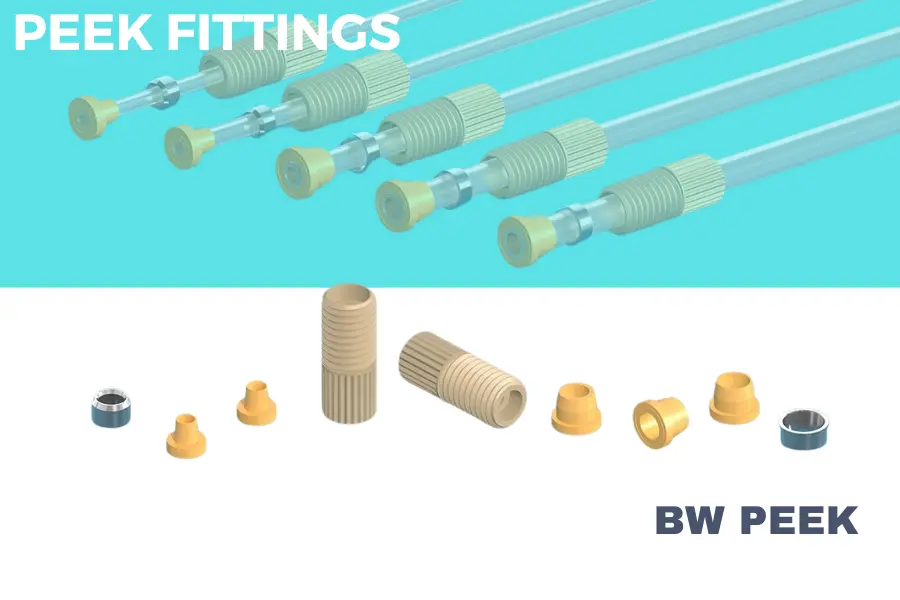

PEEK (natural color)

Long-term working temperature range -100℃~+250℃.

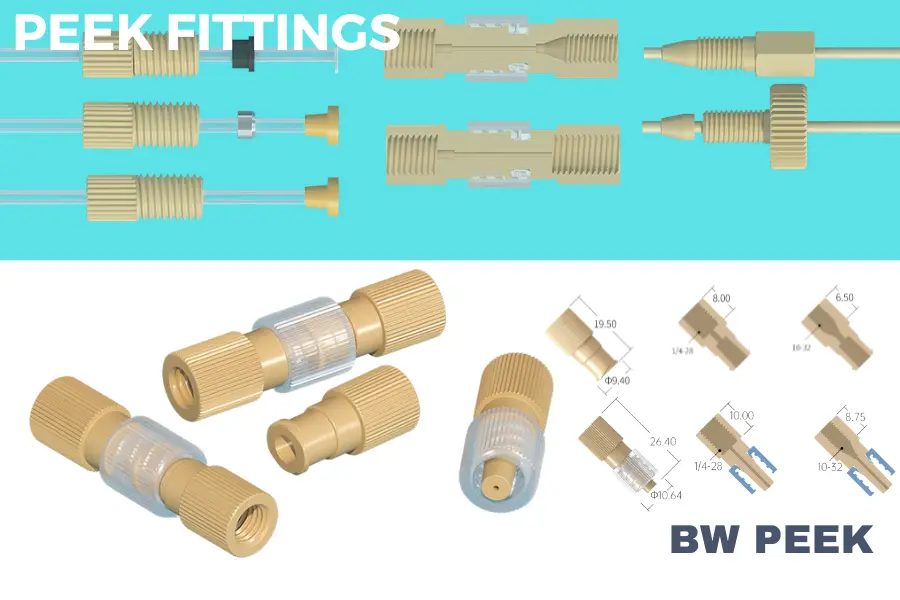

10-32UNF threaded tapered head suitable for HPLC interface.

Original one-piece hand-tight fittings, 10-32 UNF threaded tapered head for HPLC connections.

Attention

Straight-threaded standard fittings are tool-less and economical. Only need to put the inverted cone pressure plug and pressure ring on the pipe and screw into the interface to use; need to match the ETFE inverted cone pressure ring to use.

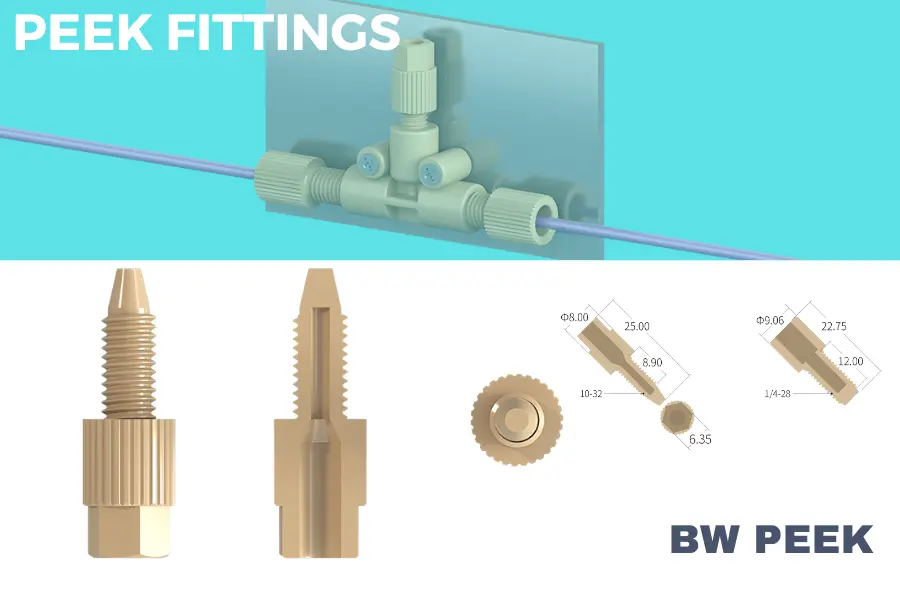

PEEK luer fittings: consist of male luer fittings and female luer fittings, the male luer is equipped with a 3.34° (luer) male taper locking fitting with a female snap ring, the female luer is equipped with a male

The male luer is equipped with a 3.34° (luer) male taper locking fitting with a female threaded female luer.

Material: PEEK, PPS

Thread size: 10-32UNF, 1/4-28UNF

Long-term operating temperature range -100℃~+250℃

Used to adapt Luer adapters to 10-32UNF or 1/4-28UNF threaded ports (pitch: 0.794mm) or 1/4-28UNF flat bottom threaded fittings (pitch: 0.907mm).

| Property | PEEK Fittings | Stainless Steel Fittings | PTFE Fittings |

| Temperature Range | -50°C to 260°C | -200°C to 800°C | -200°C to 260°C |

| Chemical Resistance | Excellent (except concentrated sulfuric acid) | Good (prone to corrosion in some acids) | Excellent |

| Weight | Lightweight (density ~1.3 g/cm³) | Heavy (density ~8 g/cm³) | Lightweight (density ~2.2 g/cm³) |

| Biocompatibility | High (USP Class VI certified) | Moderate (not ideal for medical use) | High (biocompatible, but less durable) |

| Mechanical Strength | High (tensile strength >100 MPa) | Very High (tensile strength >500 MPa) | Low (tensile strength ~20-30 MPa) |

| Pressure Rating | Up to 5000-7000 psi | Up to 10,000 psi or more | Up to 1000-2000 psi |

| Friction/Wear | Low friction, excellent wear resistance | Moderate (requires lubrication) | Low friction, moderate wear resistance |

| Outgassing | Low (suitable for vacuum systems) | Moderate (varies by alloy) | Low |

| Recyclability | Recyclable, environmentally friendly | Recyclable, but energy-intensive | Recyclable, but less durable |

Tip: Request a specification sheet from your supplier to verify pressure, temperature, and chemical compatibility for your specific application.

Yes, most PEEK fittings are reusable if undamaged. Inspect threads and sealing surfaces before reuse.

Yes, PEEK fittings are compatible with stainless steel tubing, provided the size and thread match. Use PEEK ferrules for optimal sealing.