The molecular arrangement of amorphous PEEK film is more chaotic, there is no obvious crystallization area.

Semi-crystalline PEEK film in the molecular arrangement of the more orderly, some of which formed a crystalline structure, there are also amorphous regions.

Performance characteristics: semi-crystalline PEEK film has high strength and rigidity, while retaining a certain degree of flexibility, its density is relatively high, good mechanical properties.

Applications: Due to its good mechanical properties and chemical stability, semi-crystalline PEEK films are commonly used in applications requiring high strength and rigidity, such as aerospace, automotive industry, electronic devices, etc.

A mineral filled polyether ether ketone (PEEK) film is a film material made by adding mineral fillers (glass fibers, carbon fibers, carbon black, calcium and magnesium silicates) to a polyether ether ketone matrix.

PEEK film is crucial in electronics and insulation since it has good properties of electrical insulation, temperature resistance, and its high chemical resistance. PEEK film provides stability to electrical current application and high-temperature environments that are now common in most product devices. This super high-performance semi-crystallized thermoplastic applied in circuit boards, connectors, and wire coverings, makes electronics products sustainable and secure.

CD and DVD motor gaskets, speaker film, circuit board substrates, 5G antenna substrates and other related components, supercapacitors

Sealing gaskets, thrust washers, motor insulation, high temperature circuit boards

Oil and gas cable wrappers, RFID tags, solenoid wire insulation, pressure sensors, flexible film heaters, conveyor belt devices, high performance labels

The aerospace sector has also heavily used PEEK film as it is less in weight and has high tensile strength as well as strong chemical resistance. The fact that PEEK film suits most of the aerospace needs qualifies it to be an excellent material to use in those parts that are subjected to harsh environments. The aircraft interior, insulation of wires, and structural components make use of the high-performance thermoplastic, which provides an increase in performance and safety.

Insulating films, thermoformed parts, carbon fiber composites, multifunctional adhesive tapes

Liquid crystal glass polishing frames, silicon wafer carriers, wafer and glass conveyor belts

| PEEK film Properties table | |||

|---|---|---|---|

| Property | Test Method | Units | Value |

| Density | ASTM D792 | g/cm³ | 1.26~1.29 |

| Average Water | ASTM D570 | % | 0.04 |

| Absorption Equilibrium,24h | |||

| Heat Shrinkage | ISO 11501 (200℃) | % | 0.8~4.7 |

| Tensile | ASTM D882 | MPa | 70~90 |

| Strength at Yield (MD) | |||

| Tensile | ASTM D882 | MPa | 68~86 |

| Strength at Yield (TD) | |||

| Tensile | ASTM D882 | MPa | 120~186 |

| Strength at Break (MD) | |||

| Tensile | ASTM D882 | MPa | 112~115 |

| Strength at Break (TD) | |||

| Elongation | ASTM D882 | % | 186~225 |

| Ultimate (MD) | |||

| Elongation | ASTM D882 | % | 145~180 |

| Ultimate (TD) | |||

| Tensile | ASTM D882 | MPa | 1993~2755 |

| Modulus (MD) | |||

| Tensile | ASTM D882 | MPa | 1964~2568 |

| Modulus (TD) | |||

| Melting Point | ISO11357 | ℃ | 343 |

| Coefficient of | ISO11359 | ppm/K | 55~60 |

| Thermal Expansion (< Tg) | |||

| Glass | ISO11357 | ℃ | 153 |

| Transition Temperature | |||

| Dielectric | ASTM D149 | KV/mm | 150 |

| Strength (25 μm) | |||

| Volume | ASTM D257 | Ω·m | 10^16 |

| Resistivity @25°C,50%RH | |||

| Dielectric | ASTM D150 (50MHz) | 3.12~3.3 | |

| Constant (50MHz) | |||

| Loss Tangent | ASTM D150 (50MHz) | 0.004~0.005 | |

| (50MHz) |

| Products name | Color | Texture | Thickness(µm) | width(mm) |

|---|---|---|---|---|

| peek films | nature or black | polished/polished | 100-250 | 1360 |

| polished/Matte | 250-400 | 1360 | ||

| Matte/Matte | 500-800 | 680 |

The selection of PEEK film in applications with high demanding is due to a combination of properties that include advanced resistance to high temperature, superior chemical resistance characteristics and good mechanical performance. PEEK film, as a high-performance thermoplastic, has very good high temperature resistance characteristics; this would make it suitable to environments where other materials would not perform. Its excellent resilience to chemicals proves the integrity of the PEEK film because exposing it to adverse chemicals does not affect its functionality, which undoubtedly strengthens its presence in crucial application. It is also reliable owing to its good mechanical properties and toughness.

When choosing the right PEEK film, one ought to take into consideration some few factors in order to attain its valid use in the intended application. These are the operating high temperature range, exposure to chemicals, and desired mechanical properties. The right decision also entails the attainment of toughness and the wear resistance needed. A painstaking evaluation is therefore necessary in choosing the best high-performance PEEK film in high stressing application.

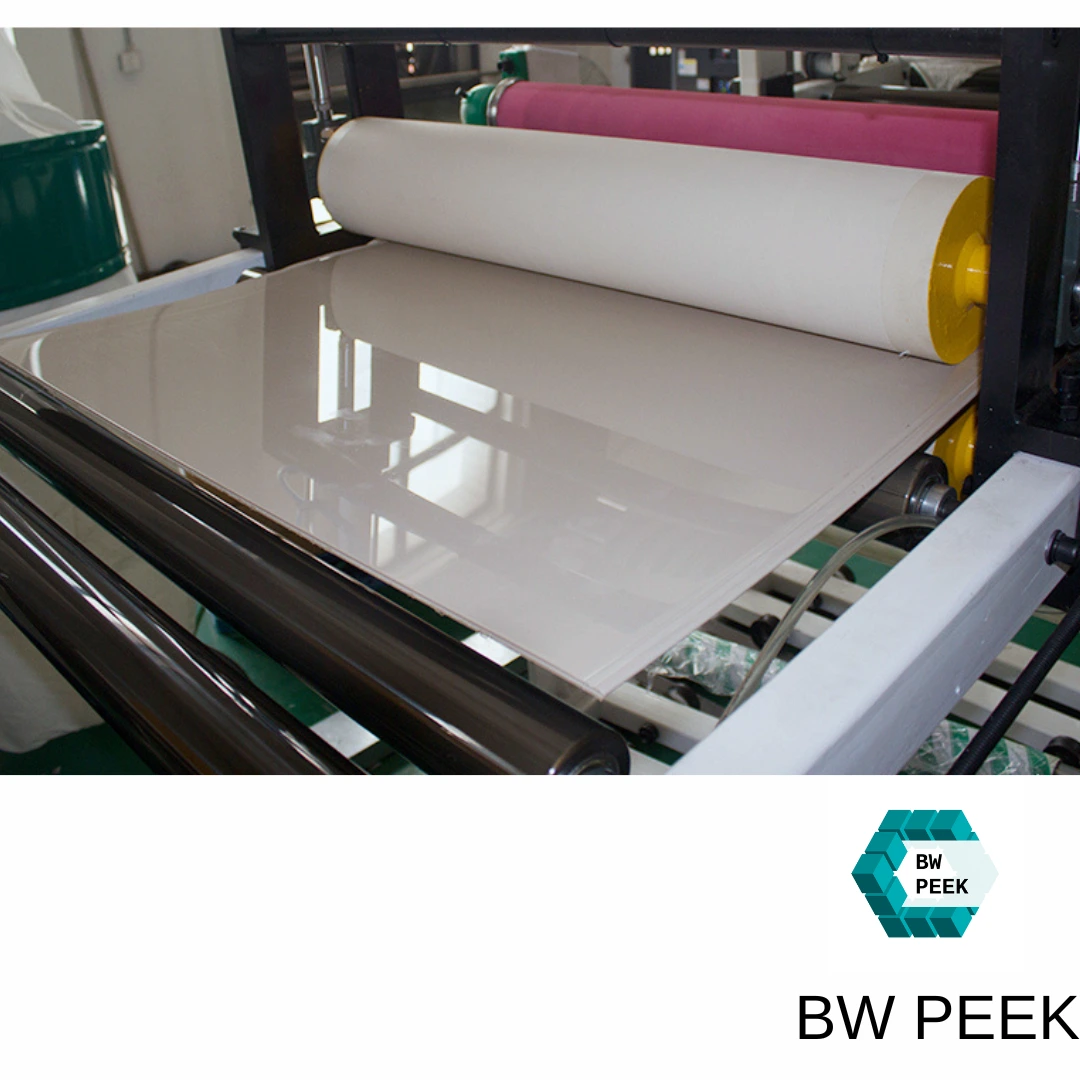

PEEK film is customizable in many different options in order to suit the needs of particular application. These can be in form of the variety of thicknesses, width, or a variety of surface treatments to promote adhesion or to minimize friction. Additives and custom coloration can also be added to give it certain electrical insulation or thermal conductivity. Engineers are able to customize PEEK film to suit the optimum performance according to these high-performance customization possibilities.