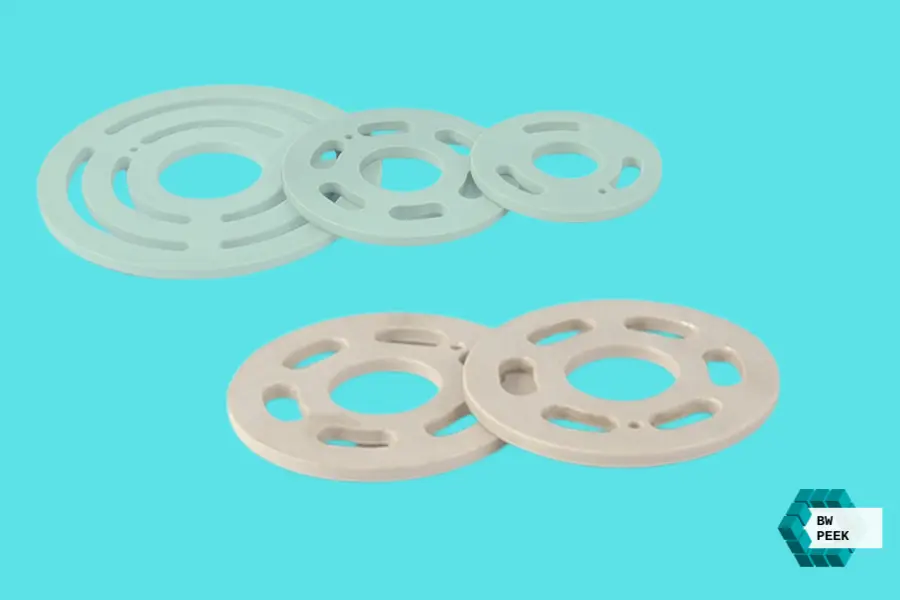

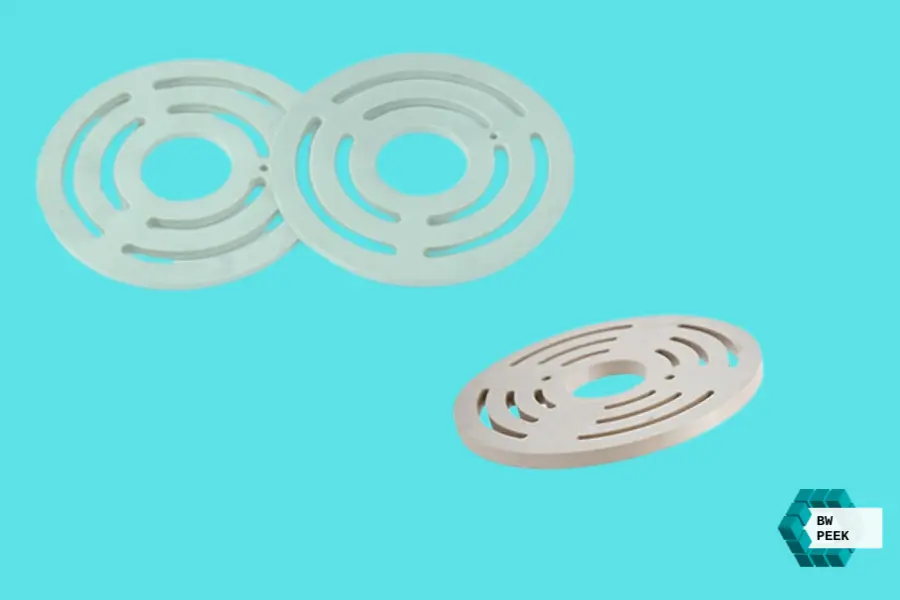

PEEK Valve Seat is one of the most efficient valve components produced from PEEK which is short for poly ether ether ketone. The commonly used material for valve seats is PEEK mainly due to its high temperature and corrosion-resistant nature.

Characterized with a melting point of 334°C and glass transition temperature of 143°C, PEEK valve plates for compressors can perform stably and steadily in high temperature and pressure conditions.

Therefore, PEEK valve plates for compressors are most suitable for pump compressor valve plates and other high temperature valve seats in nuclear power, petroleum and chemical industries.

Peek valve seats can be machined to your needs, customized PEEK compressor valve plate, our team has extensive design and production experience, especially with CNC machining.

We can develop and design an efficient, fully customized Peek compressor valve plate solution for your team.

At BW PEEK, we specialize in processing Virgin PEEK, Glass Fiber PEEK, and Glass Fiber Reinforced PEEK in various filled compound grades. Thanks to our years of experience solving valve problems, call us for professional and engineered solutions.

| Material | Temperature | Chemical | Mechanical | Wear | Cost | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| PEEK | Up to 260°C | Excellent | High | Very High | High | Superior mechanical properties | High cost |

| Excellent wear and chemical resistance | Difficult to seal due to hardness | ||||||

| Low moisture absorption Flame retardant | |||||||

| CF PEEK | Up to 280°C | Excellent | Very High | Very High | High | Extremely high mechanical strength, stiffness | High cost |

| Excellent wear resistance&low friction. | Potential for increased compared to unfilled PEEK | ||||||

| GF PEEK | Up to 250°C | Excellent | High | High | High | Improved mechanical strength, dimensional | Lower mechanical properties than CF PEEK. |

| resistance compared to unfilled PEEK. | Potential for increased abrasiveness. | ||||||

| PTFE | Up to 260°C | Excellent | Low | Moderate | Moderate | Low friction coefficient | Prone to deformation under high pressure |

| Good chemical resistance | Not suitable for high-load applications | ||||||

| Flexible at low temperatures | |||||||

| POM | Up to 100°C | Good | Moderate | Good | Moderate | Good mechanical properties | Limited chemical compared to PEEK &PTFE |

| Excellent dimensional stability | |||||||

| Easy to machine | |||||||

| UHMW PE | Up to 80°C | Good | Low | Very High | Low | Extremely low friction and excellent wear | Poor high-temperature performance |

| Cost-effective | Limited mechanical strength | ||||||

| Good impact resistance | |||||||

| DELRIN | Up to 100°C | Good | Moderate | Good | Moderate | Good balance of strength and flexibility | Limited chemical resistance |

| Easy to process and machine | Not suitable for high temperatures | ||||||

| Metals | Varies | Varies | Very High | Moderate | High | Exceptional strength and durability | Corrosion issues unless coated |

| Suitable for high-pressure applications | Heavier and less flexible than polymers |

PEEK Valve seat can sustain its strength in an environment up to 260°C which is ideal for controlling high-temperature fluids.

It was also observed that PEEK Valve seat has an excellent resistance to many chemicals. It can be used for a long time in corrosive areas without affecting the valve's reliability and safety.

PEEK Valve seat has high levels of strength and stiffness which are further comparable to metal materials; the material can handle high loads and alternating stresses leading to increased service life.

Because it has relatively high thermal stability and a low coefficient of thermal expansion, the dimensional stability of PEEK Valve seat is good when used in applications involving exposure to changes in temperature and humidity.

From the UL94 V-0 rating, it is evident that PEEK Valve seat has improved on its heat resistance; this material does not ignite aself-extinguishhes hence enhancing safety in sensitive applications.